COBUS STAIRS SOFTWARE

The program is dedicated to enterprises specializing in the production of stairs. It allows you to quickly generate code for a CNC machine based on an imported project from an external program. The application enables the import of DXF files from CAD programs used for the construction of stairs, i.e. Compass and StairCon, and then automatically assigns the types of machining to individual operations to perform the element e.g. tool paths, order of operations, types of machining e.g. milling, sawing, drilling.

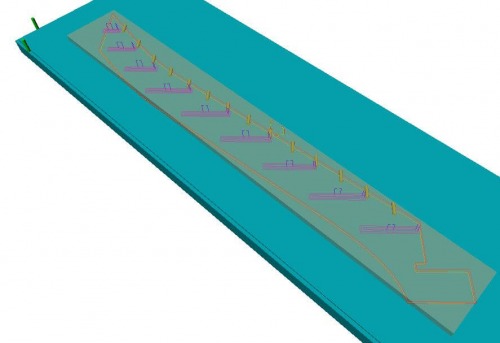

rides. The program gives the possibility of editing created automatically technological processes such as changing the processing tool, path, milling depth, as well as 3D simulation of the process to eliminate errors before generating the final code on the machine. The program generates files compatible with most CNC machines available on the market. An additional advantage is the ability to stop the machine with the STOP function with the spindle departure to safely change the material clamping or remove waste. "}" data-sheets-userformat = "{" 2 ": 4865," 3 ": {" 1 ": 0}," 11 ": 4," 12 ": 0," 15 ":" Lora "}" > The application also automatically adjusts the machining to the size of the mat, including e.g. milling depth, number of cutter passes or pocket width, including automatic insertion of additional passes. The program gives the possibility of editing created automatically technological processes such as changing the processing tool, path, milling depth, as well as 3D simulation of the process to eliminate errors before generating the final code on the machine. The program generates files compatible with most CNC machines available on the market. An additional advantage is the ability to stop the machine with the STOP function with the spindle departure to safely change the material clamping or remove waste.

STAIRS most important functions (NCAD + import stair design in DXF)

- Intuitive operation with supportive graphics

- Backup copyimplemented by auto save

- Function to create your own macros (templates)

- Drilling macros

- Features of importing a project file

- Features of element design

- Management of tools, aggregates and equipment of the machine on which the code is written

- Editing technological parameters, machining paths, tools etc.

- Automatic CNC code generation

- Control the size of internal radii when generating cnc code

- Defining the roughing and finishing depth

- Hole, pocket and corner and other machining

- Feed rate adjustment for corners and small radii

- Error alert when exceeding the set feed limit

- 3D simulation with calculation of machining time

- Support for up to 5 axes (indexed)

- Programming even several machines in one environment

- Configuration of postprocessors for all types of machines and controls