Check out the available configurations

Vertical machining centers by ATMSolutions have been created for the production of components in a wide variety of industries, ranging from simple components, molds, through complex components for the automotive industry, to such a precision industry as aviation.

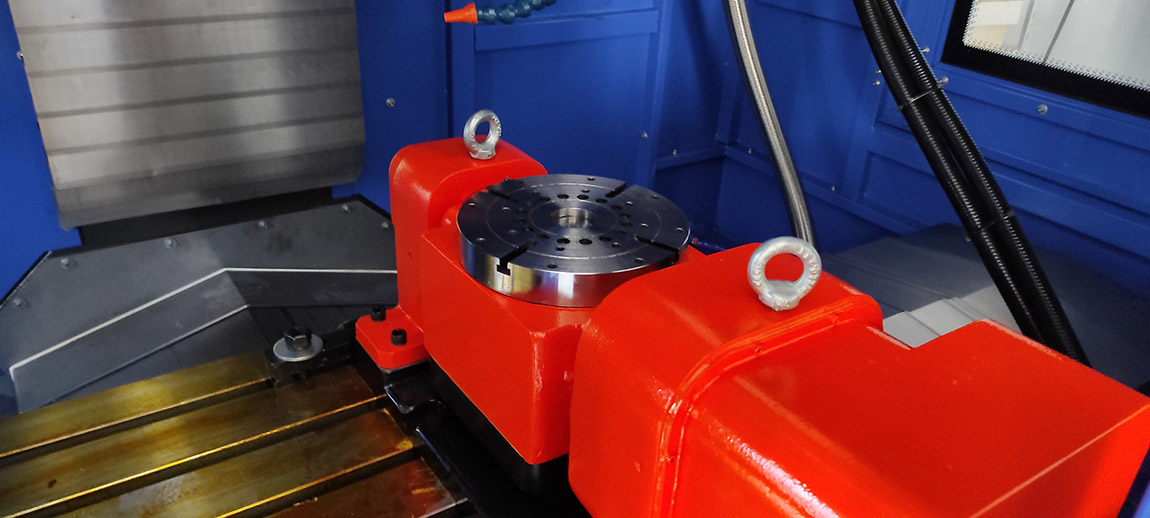

Dedicated to advanced manufacturing tasks, ATMSolutions' vertical machining centers feature industrial numerical control installed in an external operator panel. Advanced technology, operator-friendly software allow to automate and increase the efficiency and reduce the cost of the manufacturing process. ATMSolutions machining centers allow to perform machining of simple and complex multi-walled workpieces, also in one clamping. It is possible to carry out machining using an automatic, pneumatic tool changing system and the fourth and fifth axes in a simultaneous or indexed manner - depending on the selected configuration and equipment.

The ATMSolutions RPM Center is created with the utmost safety in mind. The carefully sealed enclosure is designed to protect the operator from debris during the machining process and the high-strength glass allows observation of the process being performed.

The machine tool is equipped with a water gun for manually rinsing the wiórs and a pneumatic gun for cleaning the workpiece with air. All this will allow us to keep the machine tool clean and in good condition for many years.

Increase the efficiency of your production and the precision of your workpieces - opt for a machining center from the Polish manufacturer ATMSolutions!

BALANCES OF ATMSolutions' VERTICAL ROTARY CENTERS

.- Industrial-grade, reliable control to realize and control the process of machining .

- Cast-iron machine tool body and cross-table bed design to increase the rigidity of the machine and improve the accuracy of workpiece production.

- The machine's features include the following.

- Machine parameters such as working area, table load capacity and accessories adapted to future production tasks .

- High-performance spindles with external cooling system .

- Importable systems: tool storage, vortex conveyor with tank, automatic lubrication system, water gun and pneumatic gun for removal of vortices generated during machining .

- High-end components - i.e. guides, servo motors, and spindle and air gun for cleaning the workpiece with air guarantee accurate machining and long life of the machine tool.

- High safety standards thanks to an enclosed housing for operation in the harshest industrial conditions. Safety interlock and automatic shutdown function. Sliding door with glass to protect the operator with the possibility of observing the process. .

- Guarantee provided directly by the Manufacturer - ATMSolutions .

- The knowledge and experience of the ATMSolutions Team in the field of machine construction and maintenance service allow us to provide high quality support to Usersós and efficient and full service of machines both during warranty and post-warranty time .

- Spare parts warehouse in Poland .