Check out the available configurations

CNC BASIC MILLING PLOTERS

.

Basic series milling plotters are devices thatóre perfect for industries such as advertising, industry and services. They are used for machining soft metals, plastics, compositesów, wood or various types of foams, rubbers. This series is characterized by an affordable price while maintaining a rigid design and using high-quality componentsów. It is implemented not only in small and medium-sized enterprises, but also in large production plants taking over a large part of the tasks of the processing centers.

This uses a linear guiding system and a digital driveów system thatós smooth rotation. Brushless spindles ensure stable and quiet operation, even at the highest speeds, which are controlled by an inverter. It is important to highlight the control solutions, which are intuitive and operator-friendly. The machine works in a full 3D environment. The Basic series can be enriched with additional equipment, such as vacuum tables, vacuum extractors, tool cooling systems, spindles with different powers. We also make configurations according to individual customerós needs.

.

CNC POWER MILLING PLOTERS

.

The POWER series of machines is distinguished by a more rigid and robust design. The use of reinforced steel profiles ensures precise and accurate machining, eliminating vibrations and deformations. For this reason, these machines are used in many industries, such as industry, automotive, carpentry, woodworking, plastics machining, electronics, services, in-house production and many others. Many typesóof materialsóare processed, from foams, rubbers, wood, plastics, ending with metals such as copper, brass, aluminum, bronze. The POWER series uses professional running systems, high-quality bearings and gears. Combined with advanced digital drives, they guarantee smooth rotation. The intuitive control systems used will satisfy both experienced operatorsóve and those whoóre beginning their adventure with CNC.

Equipment in the POWER series can be upgraded according to individual customer requirements. Already included is a hybrid vacuum tableó with rotary zones and additional T-slots together with a vacuum pump. The tables can be selected according to the preferences presented. The POWER series is equipped with a linear tool storage - this feature significantly shortens the machining processóbing and increases work efficiency.

CNC PRO MILLING PLOTERS

.

The PRO series refers to professional machines for use in industrial, construction, foundry, furniture/carpentry, advertising, etc. industries. They are characterized by reinforced and more massive construction, which affects the high accuracy and rigidity of the equipment. The use of professional control solutions will satisfy the most demanding operatorsów. The use of high-end mechanicalós and electronic components guarantees reliable and smooth, dynamic operation.

.The drive is realized by systems of digital servo motorós type combined with linear guides and high-quality gears. High-powered spindles ensure quiet operation and the ability to mount larger diameter tools. Already included is a hybrid vacuum tableówith rotary zones and additional T-slots together with a vacuum pump. The tables can be selected according to the preferences presented. It also uses linear tool storage - a feature that significantly shortens the machining process and increases work efficiency.

CNC INDUSTRIAL MILLING PLOTERS

.

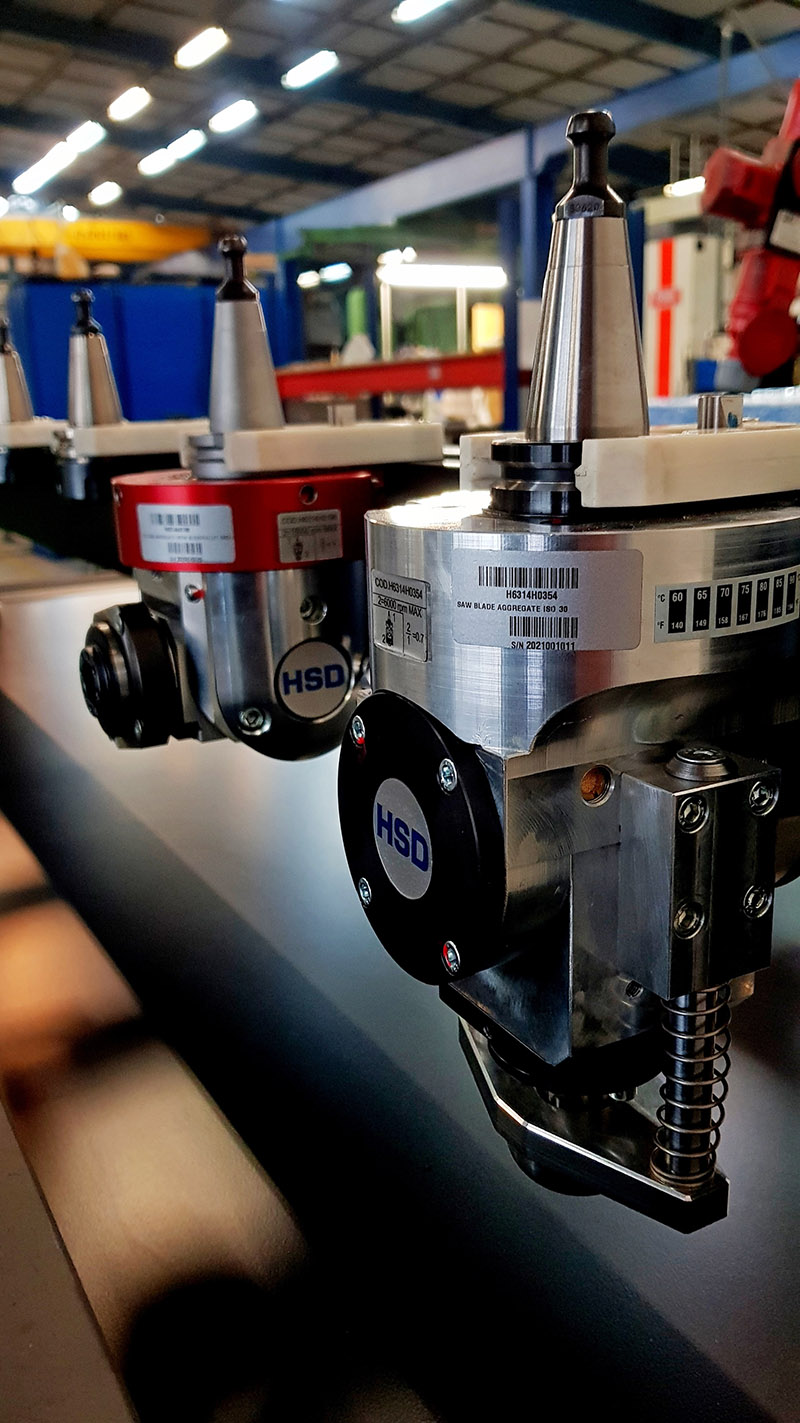

The INDUSTRIAL series represents equipment designed mainly for the industrial, construction and automotive industries. It is characterized by the use of massive construction and top-class componentsós - servo motors, linear guides, gearboxes and advanced controlós systems. The series are characterized by the possibility of almost any expansion according to individual customer requirements. There is an option here to implement multi-axis controls and realize additional axes in almost any form - rotary adapters, tilting axes, setting axes with angle units, oscillating knives, drilling units and many others. These are also machines that can be expanded with additional systems for receiving/feeding the material to be machined, additional tables to extend the working field, tool storage and extraction systems.

.