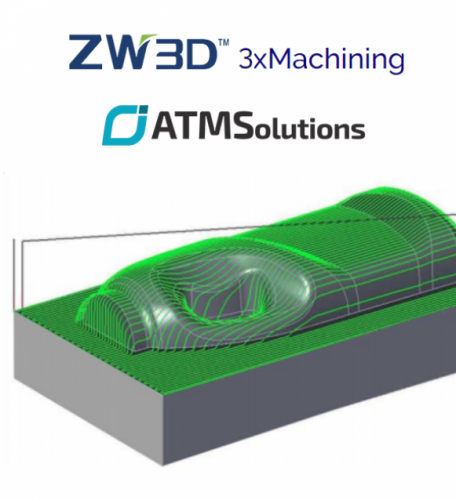

ZW3D 3X MACHINING

ZW3D 3xMachining - CAD models

- CNC milling and turning - advanced functions

The 3x module ensures optimization of CNC machine operation, cnc programming and cnc control .

3xMachining has the basic CAD functionality (the same as the ZW3D 2xMachining module ), i.e. it enables:

- solid modeling

- surface modeling

- creating 2D documentation

- creating assemblies

Built-in translators allow direct reading of the most popular CAD systems: SolidWork, Inventor, CATIA, CREO / Pro / E, NX .

1. 3-axis milling on solids

All types of treatments:

- roughing

- Finishing , HSM (High Speed Machining)

- processing leftovers (reference operation and reference tool)

- plunge machining

Different machining strategies:

- 2D offset,

- 3D offset,

- lace,

- Z levels

- pencil processing,

- 2D and 3D engraving,

- influence of curves,

- guide curve.

Unique features:

- Tool wrap angle control

- 14px; "> Giving paths waviness (trochoidal, sinusoidal processing)

- Advanced feed control

- Collision Analysis

- Undercut machining

- Negative allowances

Manually editing the CAM path and checking NC files during milling and turning .

Quick Mill technology

2. 3-axis milling on NURBS surfaces

- Roughing, machining allowance (casting) and finishing

- Detection of surface IZO curvature during milling

- The milling direction can be forced

- Macro Input / Output Wizard for tool and path connections

3. Milling 3 + 2 axes (3 continuous axes and 2 indexed axes)

- Circular interpolation support in main planes during milling

- Drilling cycles embedded or emulated on G0 and G1

- Translation and rotation of local coordinate systems

- Support for many machining databases during milling

- Control of cutter transition between successive positions

In addition, the user can use:

- CAM templates

- Machining tactics 3x milling (automatic machining of parts using 3x milling )

- Machining limits (profiles, surfaces, angular, due to the size of the processed area)

- Postprocessor generator

The possibilities of the 3x Machining ZW3D 2017 module

Video showing the capabilities of the 3x Machining module in the field of 3-axis milling. Please note that the 3x Machining module also contains 2x Machining and Lite (CAD).

V-bit engraving:

The video shows the generation of v-bit engraving. They can be used, among others in the production of decorations or markings for details.

Advanced Feed Control:

Active feed control is a useful function because it gives the opportunity to increase tool life when working on a CNC machine. Thanks to properly defined parameters, the ZW3D CAD / CAM software dynamically modifies the tool feed values, reducing them in places where the tool is more loaded. In this way, the program optimizes the work of cnc machines .

Drilling tactics:

The video presents a way to automate drilling machining in ZW3D. Thanks to this solution, the user has the ability to generate drilling operations on the entire detail with just a few mouse clicks.

Tool path editor:

This tool allows you to trim, lengthen and combine the movements of the cutter. Due to the fact that changes are already made to the generated tool path, the whole process only takes a few seconds.