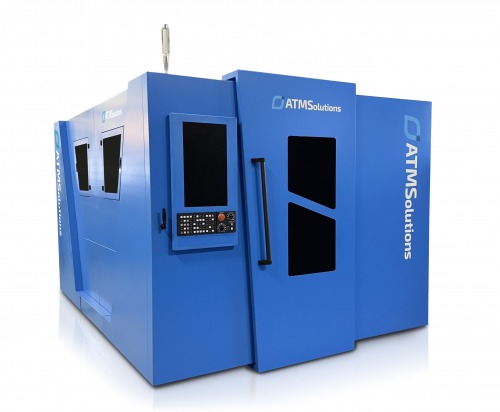

FIBER LASER CUTTER ATMS 1020 4KW EXPERT

FIBER ATMS 1020 4KW EXPERT LASER CUTTING MACHINE is a specialized laser machine tool used mainly in heavy industry, manufacturing plants and wherever long-term, trouble-free operation is required. It has been equipped with a work table that extends automatically to an unloading area located outside the machine housing, allowing to automate the machining process. It is a perfect solution for production plants, for which practical use of the machine and its capabilities counts.

The laser cutter uses proven components and control software directly from reputable manufacturers. The head design allows the operator to easily perform basic maintenance. The laser beam feed from the resonator to the cutting head is realized by means of a suitable optical fiber made and arranged in the machine structure so that it is maintenance-free and does not require maintenance or inspection. The fiber-optic cable supplying the beam from the resonator to the head is equipped with a safety circuit to prevent operation of the machine in case of damage.

.By working with Mitsubishi Electric on solutions for the CNC industry, efficient and easy-to-use solutions have been developed to maximize the time and cost of component production.

One of the main advantages of using a Mitsubishi product is the dedicated single software package for all controllers:

.- .

-

NC Monitor2 - monitoring of CNC controls via Ethernet

. -

NC Explorer - ability to transfer programs over Ethernet

. -

NC Configurator2 - ability to create backups and compare them

. -

NC Designer2 - creation of dedicated screens

.

Control system provides, among other things:

.- .

- .

automatic detection of the sheet position and matching of the tool path to its position,

. -

possibility to engrave lettering on cut details using a laser beam,

. -

automatic calibration of the cutting head nozzle height adjustment system,

. -

implementation of head protection against collision with the workpiece (e.g., in case of incorrect alignment of the workpiece or sheet being cut).

The design ensures operator safety, and the intuitive operator panel allows for convenient and comfortable operation.

The machine has numerous protections against, among other things, the effects of a drop in gas supply pressure below the permissible value. The unloading zone is equipped with a set of optical barriers, the main purpose of which is to detect the presence of people or objects in the working area of the machine. If such a situation is detected, the operation of the machine is automatically stopped.

The monolithic structure of the cutter is designed in such a way that the influence of the environment (temperature, pressure, humidity) is reduced as much as possible. Disturbances from the environment are isolated and internal vibrations are absorbed by the structure, ensuring ideal laser beam guidance. The base surfaces of the linear guides and drives were made in a single mount on a suitable machine tool. The machine has been subjected to vibration tests and multiple analyses of the characteristics of various components confirming compliance with applicable European standards.

The Fiber laser source is distinguished by a negligible laser beam deflection with a service life of more than 100,000 operating hours. The cutting edge is smooth and remains burr-free - therefore, additional edge processing is unnecessary, saving considerable time. The laser is characterized by very good thermal efficiency and high electro-optical performance. This allows it to work properly during long periods between maintenance - thus saving funds and time. We guarantee outstanding precision and exceptional energy efficiency.

In addition to cutting, the machine has the ability to engrave on workpieces.

The implemented CAD/CAM/CNC software has many useful functions integrated on a single workstation, including features:

.- .

- .

load, edit and correct files in dxf format,

. -

nesting – automatic distribution of elements on the sheet,

. -

generation of the tool path with the possibility of its correction by the operator,

. -

determination of cutting time and cost for individual projects,

. -

control all key states and parameters of machine operation,

. -

visualization of the cutting process,

. -

implementation of the cutting process of subsequent parts in parallel with the implementation of the cutting process of previous parts,

- .

-

direct (local) and remote diagnostics of the machine via the Internet.

It is possible to install the software on another computer workstation in order to prepare the work for the operator.

.CONSTRUCTION AND TECHNICAL PARAMETERS:

.-

CNC control:

. -

Manufacturer: Mitsubishi

. -

Construction: rigid, welded, monolithic, self-supporting (no foundation required)

- .

Working area: 1000 x 2000 [mm]

. -

Clearance under nozzle: 100 mm

. -

Working space enclosure

. -

Workspace access:

. -

Through a secure door located on each side of the machine tool

. -

Working field view:

. -

By means of a certified safety glass mounted on the front door

. -

Work table:

. -

Extended automatically to an unloading area located outside the machine housing

. -

Fitted with a locking system

. -

Height of the upper surface of the working table (counting with respect to the floor surface): 850 mm

-

Maximum table load: 650 kg/m²

. -

Laser source:

. -

Source type: FIBER

. -

Source power: 4kW

- .

Source manufacturer: MAX Photonics

-

Method of resonator cooling: radiator

. -

Cutting head:

. -

Manufacturer: Raytools

. -

Cutting head equipped with:

. -

Distance sensors (capacitive) providing constant, rapid measurement of the distance of the head relative to the workpiece, whose task is also to prevent collision of the head (so-called anti-collision system) with the workpiece (e.g., in case of incorrect alignment of the cut workpiece or sheet)

. -

Calibration of the nozzle height adjustment system is performed automatically

. -

Positioning accuracy of the head: 0.01 mm

. -

Drives:

. -

Drive type X,Y: servo drives

. -

Manufacturer: Mitsubishi

. -

Maximum travel speeds in axes:

. -

X: 120 m/min

. -

Y: 120 m/min

. -

Z: 70 m/min

. -

A set of optical barriers in the unloading zone: the optical barriers interrupt the movement of the work table in case of intrusion into the unloading zone during the movement of the work table, when the presence of personnel there could pose a danger

-

Drawer system: a system for collecting and removing waste falling below the work table

. -

CAD/CAM/CNC design software:

. -

Software language: Polish

. -

License: perpetual

. -

Integration with the machine control system enabling the import of files in dxf format and their editing, automatic distribution of details on the sheet (nesting) and processing into a control (execution) program

. -

Control system:

. -

Manufacturer: Mitsubishi

. -

Separate industrial computer used only for user interface

. -

Separate hardware interpolator to manage machine movements

. -

User interface computer:

. -

Operating system:Windows version 10 and higher

. -

Capable of storing up to 120 GB of user data

. -

Capable of connecting to an Ethernet network via RJ45

. -

Operator panel:

. -

Built in machine

. -

Equipped with a 24” color monitor, full keyboard, mouse, and a USB connection for reading data from removable memory sticks

-

Dust collection: fully integrated into the machine

. -

The machine is designed for simultaneous supply of oxygen and nitrogen with the possibility of automatic change of gas type and pressure adjustment by the operator from the operator panel

. -

Protection against the effects of a drop in gas supply pressure below the permissible value

. -

Pressure in the compressed air system supplying the machine: 7 bar

-

Capacity of compressed air system feeding the machine: 100 l/min

-

Nitrogen supply pressure: 30 bar

-

Oxygen supply pressure: 10 bar

-

Total electrical power required to power all machine components: approximately 32.5 kW

. - .

Dimensions of the area necessary to set up the complete machine including associated equipment (resonator, dust collector, cooler) taking into account the required distances from walls and ceilings: about 9000x6500x3000 [mm]

. - .

Humidity of room air: not more than 80%

. -

Operating temperature range: from 15ºC to 35ºC

. -

Machine supply voltage: 3x400V 50Hz

STANDARD EQUIPMENT:

.-

Dust extraction

. -

Mitsubishi control system

. -

Design software

. -

Raytools cutting head

. -

Cutting head

. -

Cables

. -

Mitsubishi drives

. -

Parts package:

. -

Cutting head protection lenses: 10 pcs.

-

Cutting heads: 10 pcs.

-

Ceramic insulators: 10 pcs

-

Set of specialized tools

.