Check out the available configurations

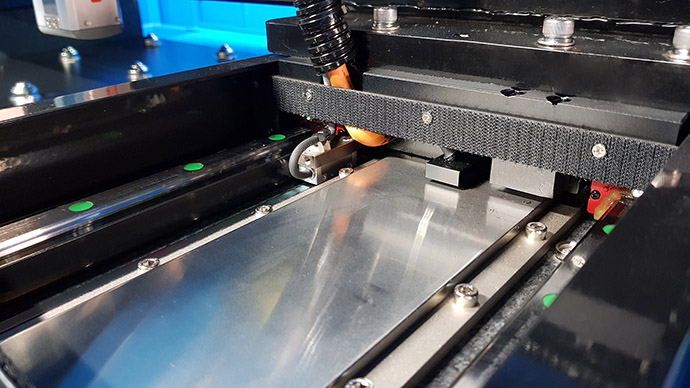

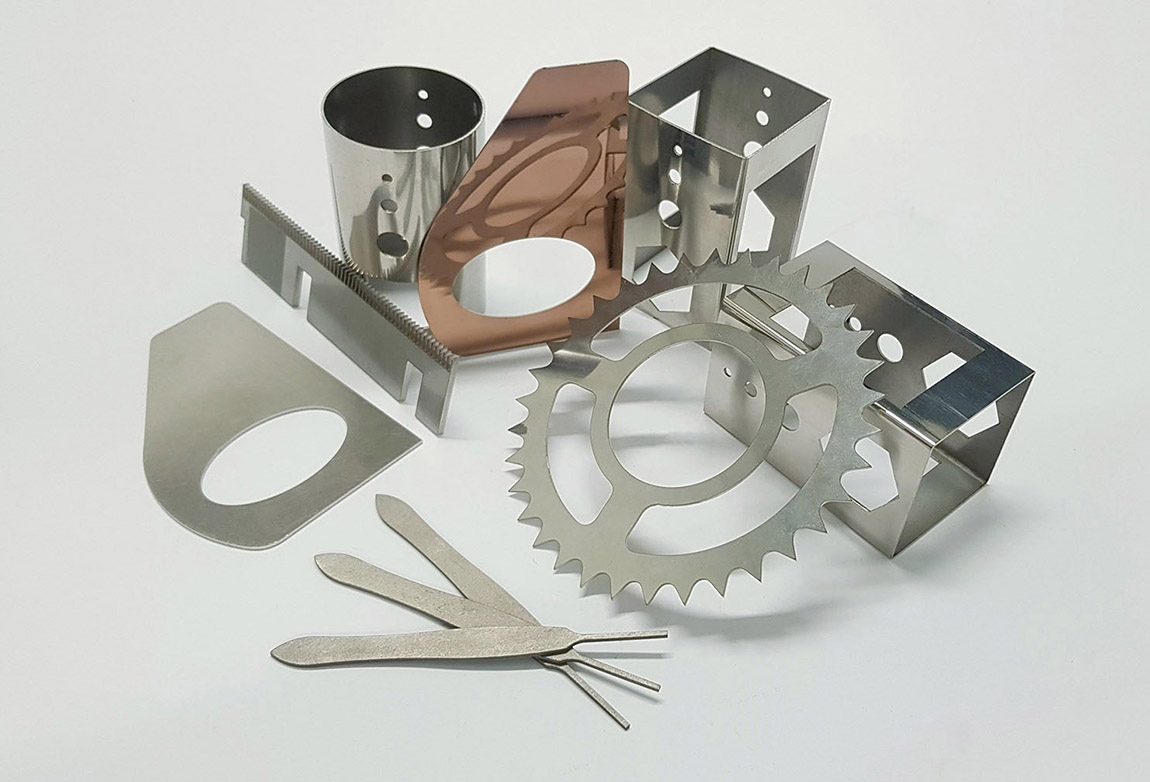

Numerically controlled fiber ATMS laser cutters are state-of-the-art machines for modern enterprises to precisely and quickly cut any shapeó from sheets of stainless steel, carbon steel, aluminum, copper, titanium or to realize rotary machining of pipes and profiles. There is no doubt that performing accurate cutting without the need for further finishing&óbing makes it possible to speed up series production. Using ATMSolutions' fiber laser systemsó you will experience a new dimension of cutting. You will cut details, cut round or rectangular profiles and get a perfect, smooth cutting surface without burrsós.

Fiber laser cutters manufactured by ATMSolutions are customized each time to suit the machine's future applications. The selectionór of configurations refers to the adjustment of the working field, the power of the laser sourceód and the manufacturer of the sourceód, extraction systemsód, or compatible optional equipment of the machine for process automation.

.

PROFESSIONAL CONTROL

.The machine is designed for continuous industrial operation. It is equipped with an intuitive, easy-to-use control system with a dedicated operator panel, whichóry also ensures stable and precise guidance of the laser beam. For proponentsóof mobility, the machine is also equipped with a tasker.

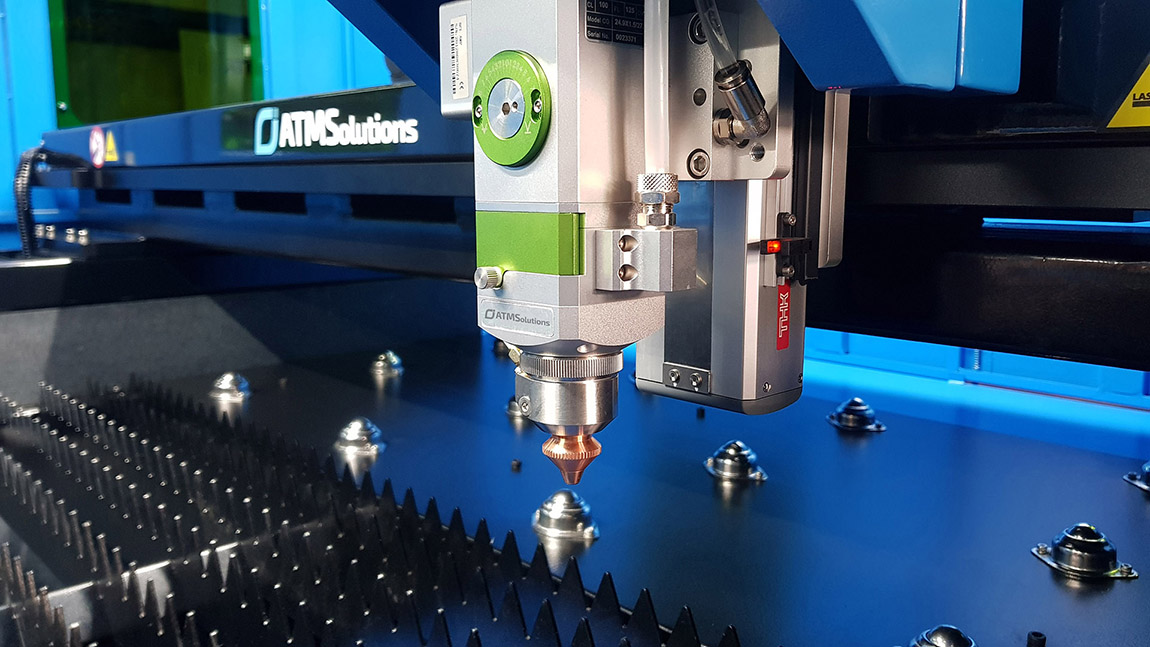

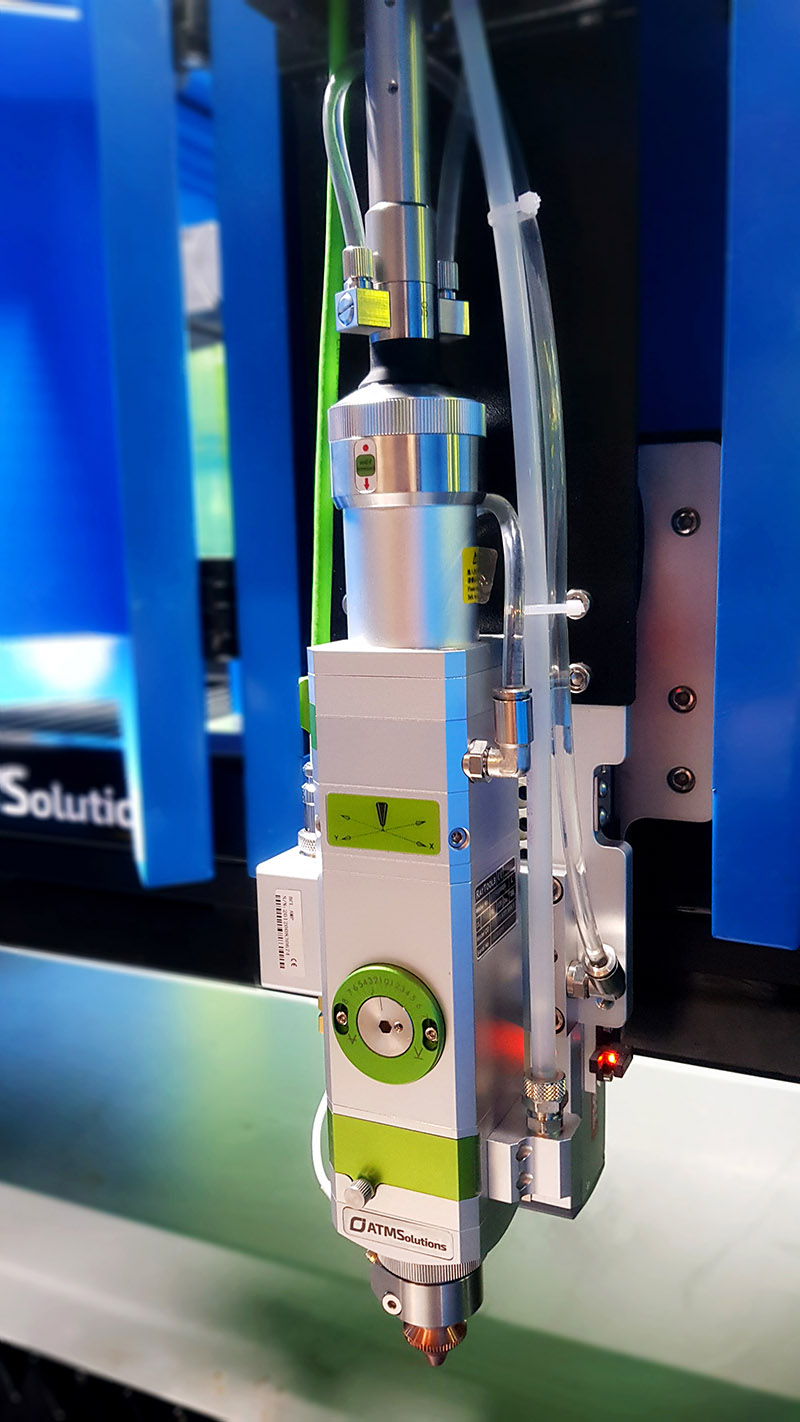

HIGH QUALITY LASER FIBER GENERATOR

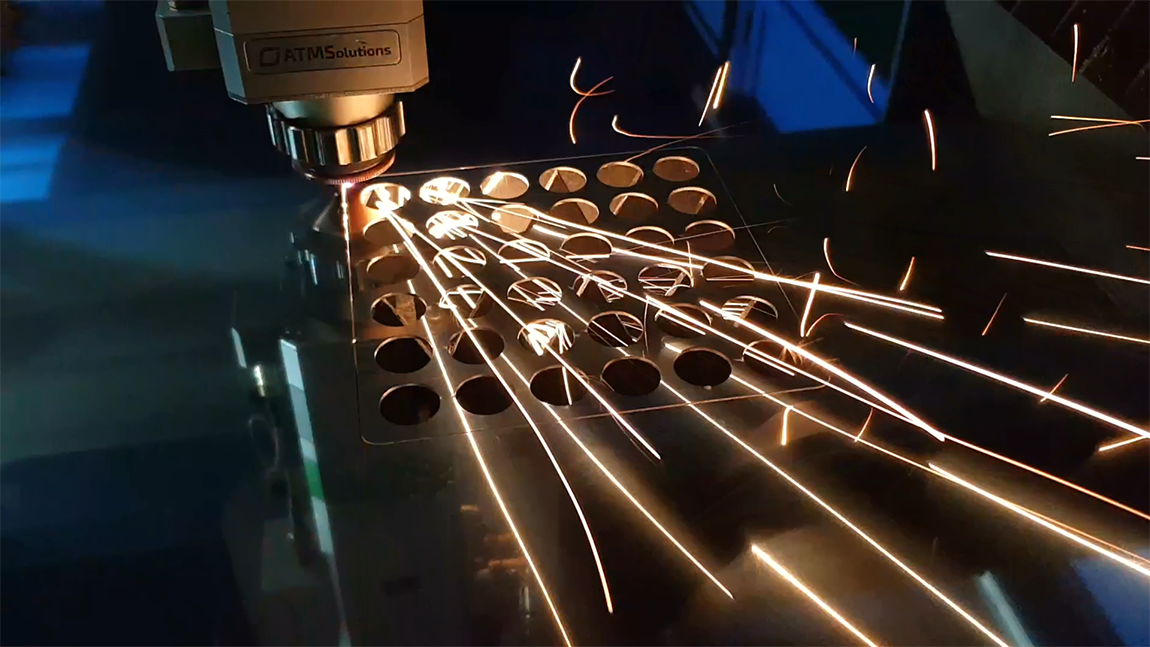

.The ATMS fiber laser cutter uses only proven fiber laser sourcesód and cutting heads from recognized manufacturersód. The fiber laser source is characterized by negligible laser beam deflection and very good thermal and electro-optical performance, resulting in a smooth cutting surface. The high quality of the laser beam generator and the use of an industrial liquid cooler guarantee a service life of at least 100,000 hours. We offer sources with power from 300 [W] to 12000 [W] selected according to the application.

.

Construction and Housing

.

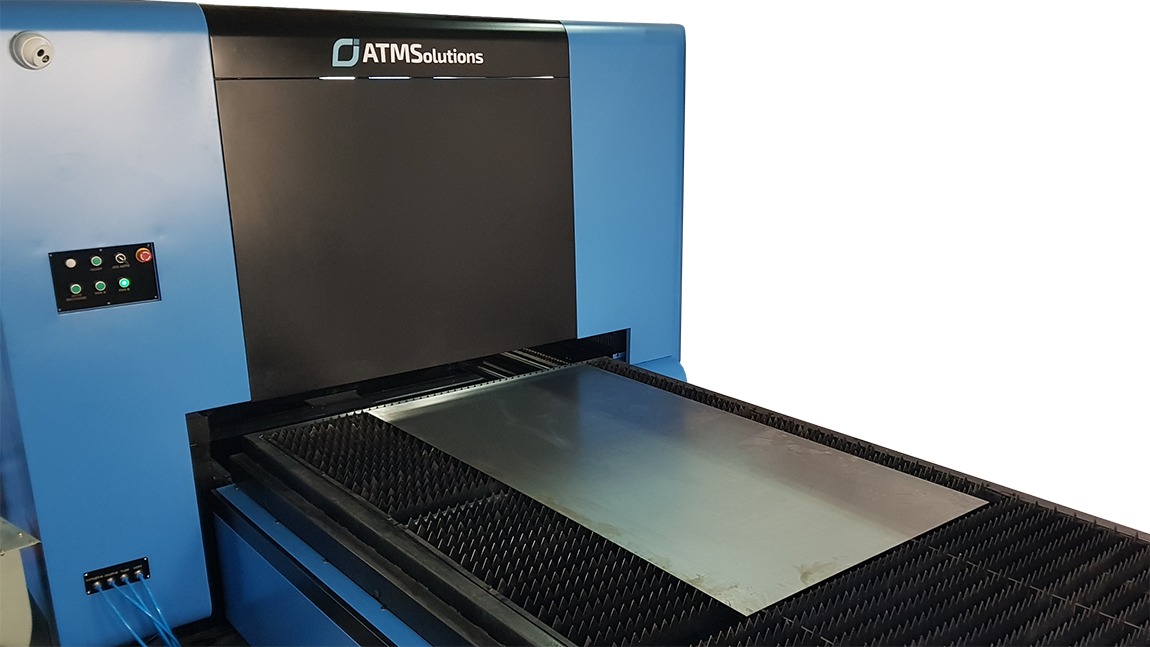

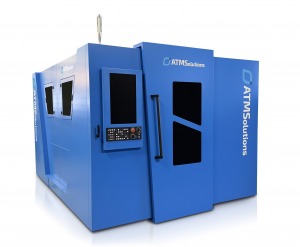

The device is characterized by a stable subframe structure and a reinforced stó?, whichó? nullifies vibrations and deformations during the cutting process. ATMS cutters are available in two constructions: open construction plotter or plotter with full work field cover. The full working field shielding is designed to protect the operator from the high-power laser beam, eliminate noise, as well as reduce the impact of environmental factors on the cutting process (temperature, pressure, humidity) and increase the precision of the laser beam guidance. To increase safety, we use safety gates or light curtains.

DYNAMICS AND HIGH CUTTING SPEEDS

.A motion system consisting of a frame system and a cutting head height compensation system is responsible for dynamic movements and achieving high speeds, with a The frame is driven from both sides of it. The choiceór of drive type is adapted to the customer's expectations. The stops, along with flexible pressure pads, are located at the ends of the motion ranges, in the X and Y axis directions. Transmission components (e.g. gears, guide systems) were produced by the world's leading manufacturersós. Working comfort is improved by autofocus or automatic nozzle cleaning system.

Productivity

.The ATMS fiber laser cutter with numerical control allows you to cut any designed details - with simple or complex contours - in a short time with exceptional quality and precision. It is possible to choose a machine with a rotary attachment for pipes and profiles, or to select a machine dedicated exclusively to the machining of pipes and profiles also with a head for working with irregularly shaped profiles.

Which FIBER cutter should you choose?

.Everyone interested in fiber laser cutter faces the same dilemma. Always, the most important thing is to answer the mainóve questions:

- What materials and what size will be processed most often ?" .

- What thickness of materials will be machined and the smallest holes will be cut? .

- Will I be looking to increase production efficiency and automate the process or will there be low-volume unit orders ?

- Will there be implemented 3D machining? .

- Does the supplier I am considering have experience in supplying machinery and does it have a technical support team and a spare parts warehouse?

As experienced fiber cutter suppliers ATMSolutions, getting answers to the above questions, we advise users what parameters the machine should have to meet the customer's expectations. It is equally important to chooseór the right supplier, who will be able to helpóc in critical situations from the entrepreneur's point of view, but simple from the point of view of an experienced supplier - the Manufacturer of the machine, whoór knows the construction of the delivered machine, is proficient in operating and maintaining it, thanks to which the risk of possible downtime due to machine failure, whichór guarantor is not able to repair, is reduced to a minimum.

Why visit a potential Supplier at a manufacturing facility?

.- Possibility to have a direct conversation and see the manufacturing process before the purchase during the presentation .

- Possibility to discuss expectations and make personalized technological próbs directly at the meeting

- Ability to evaluate the potential Supplier's after-sales cooperation and with regard to subsequent machine purchases

Why choose ATMSolutions?

.In our standards is the highest level of sales and after-sales service - we encourage you to visit our headquarters in Lomianki and see and test the machines available in the ATMSolutions machine demonstration area.

Buy risk-free! Extensive knowledge and experience backed by hundreds of reference letters from satisfied Customersóre available on our website. We have the largest customerów reference database in Poland!

A large, qualified technical support team responsible for conducting implementations, training, and warranty and post-warranty maintenance services provided directly by the Manufacturer in Polish or English

Fast response to the request and resolution of the service order thanks to well-established knowledge of the machines built by ATMSolutions and a warehouse of the most popular spare parts in Poland

Tested components and control software directly from reputable manufacturersós - as a Machine Builder ATMSolutions is an official distributor of many brands

We have CNC machines in multiple technologies - one supplier, is one machine service company - fast operation and minimize production downtimeós.

Customized configuration

.Fiber cutters by ATMSolutions are equipped with efficient fiber optic sources (IPG, MAX or Raycus depending on the specification selected) to provide precise and fast cutting of metal sheets. It is possible to configure the equipment according to individual customer needs.

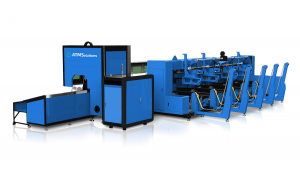

For universal applications, Cutting machines equipped with an additional interchangeable station are perfect - a solution that will ensure simple operation while optimizing the cutting process. In addition, the machines can be retrofitted with a sheet magazine with automatic loading of sheets onto the work station. This is a feature thatóra is ideal for industrial plants, where the main goal is to streamline production and save time.

.

Models that&oac;re designedfor cutting sheet metal, can also be equipped with a rotary attachment, which allows for additional processing of profiles and pipes, increasing the range of applications of the machine.

..

For customersóers who specialize in profile cutting, we offer equipment dedicated to rotary cutting - the solutions and components used in this series of machines guarantee a fast and efficient cutting process. There is also the possibility of retrofitting the machine with a parts warehouse so that the loading is done automatically, which significantly shortens the technological process.

For customersów looking for a simple and compact solution, we created the PROCOMPACT series. The advantage of this series is full built-in device while maintaining small sizeów. It is a perfect solution for those whoóre starting their adventure with FIBER technology.

..

We encourage you to take a look at ATMSolutions' offerings, in which you will find: #laseryfiber #fiber cutters #fiberlaser

.

.jpg)