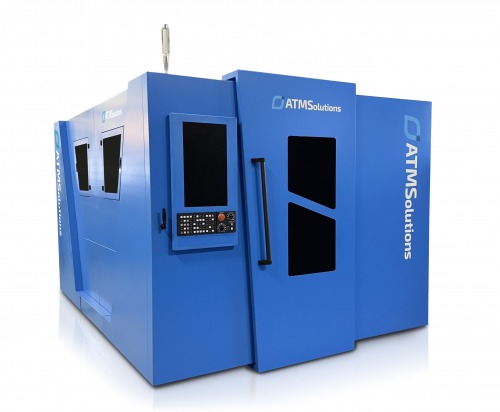

LASER CUTTING MACHINE FIBER ATMS 1530 PRO 4KW MAX WITH INTERCHANGEABLE TABLES

Laser cutting machine ATMS in FIBER technology equipped with an additional stationó? that allows to automate the process of cutting. It is a perfect solution for production plantsórs, for which practical use of the machine and its capabilities matter. ATMS FIBER 30x15 ET allows you to optimize time, combining functionality with economy - it does not require additional interruptions in production associated with changeover, cleaning, loading and unloading of workpiecesól. The interchangeable station simplifies cutting numerous shapes patterns in a repetitive process, while allowing access and control of already made parts or just being prepared.

Mainly used in heavy industry, in manufacturing plants and wherever long-term, trouble-free operation is required. Extremely stable, 2-ton support frame structure together with reinforced table ensures precise cutting leveling any deformation. Distortion from the environment is isolated and internal vibrations are absorbed by the structure, ensuring perfect laser beam guidance.

.Fiber optic cutters of the ,,PRO” series are characterized by the use of an independent control cabinet, change of control system and the use of Raytools cutting head. The built-in automatic focal length adjustment system (autofocus), the high-end 4.5t bed that guarantees high rigidity, and the extremely powerful servo drives guarantee almost perfect cutting quality regardless of the power of the laser source. It is possible to equip the machine with a full enclosure, a pipe cutting attachment and an interchangeable stationó? and use a higher power of the laser source.

Advanced laser technology goes hand in hand here with ergonomics and ease of use of the device. It is designed mainly for steel machining, primarily stainless steel and carbon steel.

Thanks to the use of the FIBER laser, the cutting edge is smooth, remains burr-freeów - therefore, additional edge cutting is unnecessary, which saves a lot of time. The device is equipped with a professional system thatóry ensures stable and reliable guidance of the light beam along with its control. The high quality of the laser beam generator guarantees its service life of up to more than 100000 hours.

Advanced laser technology goes hand in hand here with the ease of operation of the machine. The machine is ideal for industrial operation. It is designed mainly for sheet metal processing, primarily stainless steel and carbon steel. The aluminum frame guarantees consistently high axis accuracy.

BUILDING AND TECHNICAL PARAMETERS:

.- Working area: 1500x3000 mm .

- Laser source: 4kW MAX

- X-axis displacement: 1500 mm

- Y-axis displacement: 3000 mm

- Z-axis displacement: 100 mm .

- Yaskawa servo 2x 1.8 kW, 1x 1.3 kW, 1x 0.4 kW .

- X/Y positioning resolution: ±0.03 mm/m .

- X/Y positioning accuracy: ±0.05 mm .

- Maximum acceleration of X/Y axis: 0.8 G .

- Maximum motion speed: 140 m/min

- Cutting table for high rigidity: 4.5 [t] .

- Machine size: 4800 x 10300 x 2400 [mm] .

STANDARD EQUIPMENT:

.- Cutting table .

- Industrial liquid cooler for FIBER laser cooling .

- Autofocus .

- CypCut control system - with dedicated display, software, and referencing device .

- System for easy loading of metal sheets onto the work table .

- Independent control module .

- Extraction system .

- Controls

- Complete wiring .

- Full wiring .

- Toolbox .

- Guarantee 24 months .