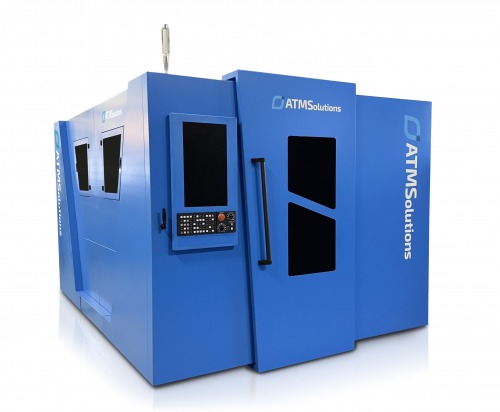

LASER CUTTING MACHINE FIBER ATMS MAX 10X20 1500W - 24H.

Laser cutting machine ATMS in FIBER technology used mainly in heavy industry, in manufacturing plants and wherever long-lasting, trouble-free operation is required. It is the perfect solution for manufacturing plantsórs, for which practical use of the machine and its capabilities matter.

The construction of the cutter has been designed in such a wayób that the influence of the environment (temperature, pressure, humidity) is reduced as much as possible. Disturbances from the environment are isolated and internal vibrations are absorbed by the structure, ensuring perfect guidance of the laser beam. The machine has been subjected to vibration tests and many analyses of the characteristics of the rós componentsós confirming compliance with applicable European standards. The design of the beams and columns has been integrated into a single stable element. The software is compatible with multiple CAD formats, energy consumption has been reduced-while keeping process stability high, ensuring easy maintenance and low cost of ownership.

The Fiber laser blade features negligible laser beam deflection, with a lifetime of more than 100,000 operating hours. The cutting edge is smooth and remains burr-freeó-therefore, additional edge trimming is unnecessary, which saves a lot of time. This laser is characterized by very good thermal efficiency, and high electro-optical performance. This allows it to work properly during long periodsón between maintenance, thus savingób funds and time.

The FIBER ATMS 2010 1.5KW model was created for demanding usersós. It guarantees outstanding precision and exceptional energy efficiency.

ATMSolutions offers machine installation, foundation and full training culminating in the issuance of a certificate.

CONSTRUCTION AND TECHNICAL PARAMETERS:

.- Laser source type: Laser FIBER MAX Photonics .

- Standard output power: 1500W .

- Working area X,Y: 2000x1000 mm .

- Clearance under nozzle: 90 mm .

- Nominal working range of motion in X/Y axis: 0-2000/0-1000 mm .

- Drive axis position measuring system: Measuring lines .

- Feed rate: 0-70m/min .

- Motor type: linear motors (direct drives) .

- Positioning accuracy: 0.04mm .

- Working table: grating with mechanical sheet locking .

- Bin for waste generated during cutting .

- System of supplying the cutting machine with technological gases from a cylinder .

- Possibility of cutting with technological gases .

- Possibility of cutting with compressed air instead of process gas .

- Automatic head height adjustment with collision protection when the nozzle comes off the material .

- Automatic detection of the sheet angle in the working space with automatic software correction .

- Automatic door locking .

- Work table load capacity: 650 kg

- Work zone vacuum dust collection system: 5.5 kW; equipped with spark catcher

- Control panel.

- Position-adjustable control panel equipped with keyboard and mouse and USB connection .

- Computer control system with software (perpetual license) .

- Storage for user programs and files: 64GB

- Color LCD monitor: 17"

- RAM: 4GB .

- Chiller with temperature stabilization .

- Construction: Self-supporting, no foundation required .

- Working area enclosure: doors on four sides, safety system, automatic internal locks, dAdditional front door lock to prevent opening during the cutting process .

- ETHERNET module .

- Free remote diagnostics of the machine via the Internet .

- Machine weight: 7000 kg

- Guarantee: 24 months .