COBUS WOP SOFTWARE

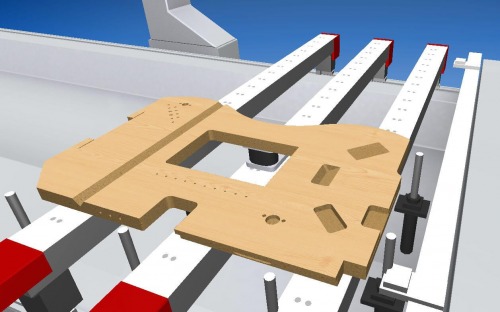

COBUS WOP software is an intuitive and easy-to-use software for rapid design and production, dedicated to woodworking machines and wood-like materials, which has been on the market for 25 years.

The program has any design functions elements, e.g. doors, windows, countertops, wardrobes, furniture fronts or other, and then automatic execution of previously designed details on a numerically controlled machine by directly generating the appropriate code taking into account the parameters of the CNC machine. The program's advantage, besides the mentioned automation, is its parametricity. The parameterization function allows you to speed up programming and code generation for a CNC machine. The universality of the program is demonstrated by the possibility of importing geometry from the most popular DXF and DXF files with described layers - communication with external CAD programs has never been so easy.

The program can also be integrated with an existing machine that does not have a modern control program by replacing the currently used control system with the COBUS WOP program, which has postprocessors for most machines on the market as well as interfaces and optimizations adapted to them.

the program allows you to control many CNC machines, use a rich macro database that includes the data of available tools, aggregates and additional machine accessories. Macros such as milling, sawing, drilling and veneering surfaces allow the operator to quickly create CNC programs as needed with a few clicks. The ability to import and edit tool data from the controller speeds up this process. \ nThe program also allows the operator to create individual work templates for a repetitive process. "}" data-sheets-userformat = "{" 2 ": 4865," 3 ": {" 1 ": 0}," 11 ": 4, "12" 0, "15", "Lora"} ">

In addition, the program allows you to control many CNC machines, use a rich macro database that includes the data of available tools, aggregates and additional machine equipment. Macros such as milling, sawing, drilling and veneering surfaces allow the operator to quickly create CNC programs as needed with a few clicks. The ability to import and edit tool data from the controller speeds up this process.

The program also allows the operator to create individual work templates for a repetitive process.

with an already owned machine that does not have a modern control program by replacing the currently used control system with the COBUS WOP program, which has postprocessors for most machines on the market and interfaces and optimizations adapted to them. \ nAdditionally, the program allows you to control many CNC machines, use a rich macro database that includes the data of available tools, aggregates and additional machine equipment. Macros such as milling, sawing, drilling and veneering surfaces allow the operator to quickly create CNC programs as needed with a few clicks. The ability to import and edit tool data from the controller speeds up this process. \ nThe program also allows the operator to create individual work templates for a repetitive process. "}" data-sheets-userformat = "{" 2 ": 4865," 3 ": {" 1 ": 0}," 11 ": 4, "12" 0, "15", "Lora"} ">

The most important WOP functions:

- Intuitive operation with supportive graphics

- Backup copy carried out by auto save

- Function to create your own macros (templates)

- Drilling macros

- Features of importing a project file

- Features of element design

- Management of tools, aggregates and equipment of the machine on which the code is written

- Editing technological parameters, machining paths, tools etc.

- Automatic CNC code generation

- Control the size of internal radii when generating cnc code

- Defining the roughing and finishing depth

- Hole, pocket and corner and other machining

- Feed rate adjustment for corners and small radii

- Error alert when exceeding the set feed limit

- 3D simulation with calculation of machining time

- Support for up to 5 axes (indexed)

- Programming even several machines in one environment

- an already owned machine that does not have a modern control program by replacing the currently used control system with the COBUS WOP program, which has postprocessors for most machines on the market as well as interfaces and optimizations adapted to them. \ nAdditionally, the program allows you to control many CNC machines, use a rich macro database that includes the data of available tools, aggregates and additional machine equipment. Macros such as milling, sawing, drilling and veneering surfaces allow the operator to quickly create CNC programs as needed with a few clicks. The ability to import and edit tool data from the controller speeds up this process. \ nThe program also allows the operator to create individual work templates for a repetitive process. "}" data-sheets-userformat = "{" 2 ": 4865," 3 ": {" 1 ": 0}," 11 ": 4, "12": 0, "15": "Lora"} "> Configuration of postprocessors for all types of machines and controls