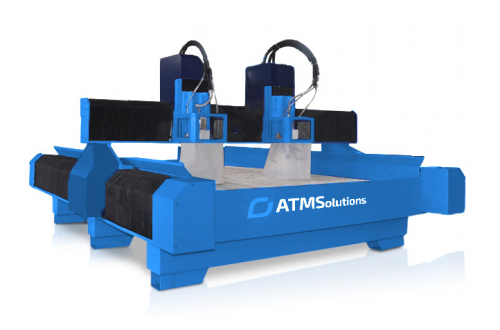

18X25 K INDUSTRIALMILL2 INDUSTRIAL PLOTTER

The ATMS K IndustrialMill2 industrial plotter has been designed for multi-tool tasks in the manufacture of products by numerical control. Designed for processing stones, marbles, minerals, granites, sandstones, terrazzo, gypsum, etc ... in industries such as mining, handicrafts and art, ornamentation, masonry.

IndustrialMill2 has been optionally equipped with 2 independently moving heads, armed with covers and liquid cooling of the tool. Thanks to this construction, it is possible to carry out more advanced projects in as much as 2 times less time and shorten the production time of serial factories. The IndustrialMill2 plotter also allows you to optimize the space of the machine park and minimize the costs associated with the production and maintenance of the device.

All ATMS milling plotters are equipped with solid frames that significantly stiffen the machine's long life structure and reduce vibration and deformation. A wide selection of spare and optional parts allows for good adjustment of the device to the customer's requirements.

Technical specifications:

- Workspace: 1800x2500 [mm]

- Working height: 300 mm

- Max. travel speed: approx. 25 m / min

- Resolution: ? 0.025 mm

- Spindle:

-Power: 3.2 kW

-Speed rotation: approx. 24000 ÷ 6000 [r / min]

-Quantity: 1

-Working direction: vertical

- Cooling: liquid

- Compatible extensions: g-code, * .u00, * .mmg, * .plt, HPGL

- Dimensions: 3500x2500x1700 [mm]

- Weight: 2000 kg

- Power supply: 380 VDC, 50 Hz

Included:

- Driver: Leadshine

- SUNFAR Inverter

- Control system: SYNTEC

- Linear guides: PMI

- Z axis ball screw: TBI

- Pneumatics: AirTAC

- Dust protection of X, Y, Z axes

- Compatibility with the system: Windows 98/2000 / XP

- Centralized lubrication

optional:

- Linear guides: HIWIN

- Driver: Panasonic

- Control system: NC-studio

- Driver: YASKAWA servo

- Delta Inverter

- Electricity: Schneider

- 4.5 kW, 5.5 kW spindles

- Number of spindles: 2

- CAM design software

- 3D modeling software

- scanning head

- DSP controller

- wireless tool height sensor enabling height control anywhere on the work table

- bath + flood cooling tools

- and other?

CONSTRUCTION AND TECHNICAL PARAMETERS:

.- Working space: 1800x2500 [mm] .

- Working height: 300 mm .

- Max. travel speed: approx.25 m/min

- Resolution: ±0.025 mm .

- Spindle:

- Power: 3.2 kW .

- Rotational speed: about6000 ÷ 24000[rpm/min]

- Number: 1 .

- Direction of operation: vertical .

- Cooling: liquid .

- Compatible extensions: g-code, *.u00, *.mmg, *.plt, HPGL

- Dimensions: 3500x2500x1700 [mm] .

- Power supply: 400 VDC, 50 Hz .