MINI MILLING PLOTTER WITH ATC TOOL MAGAZINE

Due to the constant cooperation with many education centers, schools and universities, the ATMSolutions team has prepared a complete solution that is perfect for issues related to training on the broadly understood CNC - numerically controlled machines. The device is slightly larger compared to the Mill Mill Mini Milling Machine, it is equipped with the possibility of automatic tool change, which significantly affects the efficiency of the machining process. It is a conscientiously refined product, where the emphasis was put on the smallest details, which together with the selection of appropriate components gives us probably the best solution on the market for a device with a tool magazine, taking into account the value for money. It is possible to replace the control system with others, e.g. Siemens, Fanuc, Syntec, NC Studio and some components (listed as optional equipment). There is an option to retrofit the machine with a number of different accessories and functions that can become interesting topics to be covered in all kinds of training, courses, lessons, etc. It should be remembered that CNC technology is very popular nowadays and has become widely available, already not only for large production plants, but also for small and medium-sized enterprises - therefore, the CNC course can be a great asset in the CV.

After training on such devices, it is possible to obtain CNC course completion certificates !!!

Below are the basic specifications of the machine, the final equipment of course is virtually arbitrary, each time determined individually, according to the needs of the Employer. It applies to both the mechanical part (working field, spindle power, components such as motors, guides, work table, housing, etc.) and software (various control systems and design software supporting the machining process).

The ATMS CNC Mini Milling Machine with the working field dimensions of 600x900x80 mm and is perfect for both smaller and large-scale workpieces. A wide range of materials can be processed: from metals and their alloys such as aluminum, brass, bronze, copper to plastics, wood, foams, etc. The advantages of the machine include a solid steel frame, which by increasing the rigidity of the entire machine ensures precise and accurate machining, reducing vibration and deformation. Powerful, precise, water-cooled and quiet (even at high speed) spindle with a power of 3 kW provides comfort and versatility.

The milling machine will cope well with the processing of plastics, non-ferrous metals, as well as the hardest aluminum alloys. The device works well on engraving on 2D and 3D planes as well as on rotating objects, thanks to the use of an optional 4 axis.

Construction - due to the assembly of the tool magazine, it is important to retrofit the machine with high-class components, such as the ATC spindle, reinforced structure, or motor-drives guaranteeing accurate positioning. In the basic version, the gate is movable, in addition, the T-table is equipped with grooves for convenient fastening of elements, trapezoidal linear guides and bolts with a ball nut on the Z axis. Movement in the X and Y axes is carried out on trapezoidal guides with bevel gears.

We have the ability to adapt a wide range of optional equipment and many solutions - including according to individual needs - to increase the comfort of work (listed as optional equipment below).

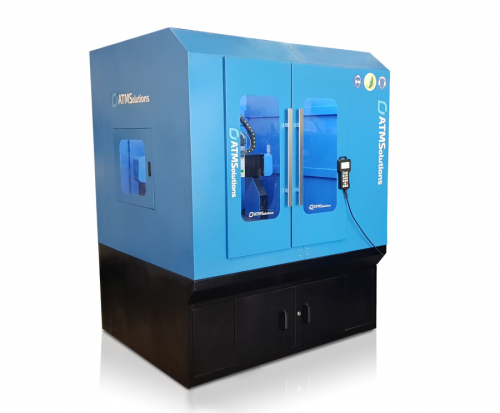

The mechanical part can be enclosed (an embodiment of one of the enclosures is shown in the picture), thereby increasing operator safetyas well as comfort and hygiene at work around the entire stand.

Additional accessories in the form of a 3D scanner mounted on the milling machine allows you to learn about reverse engineering processes, where based on a real object we get its model in 3D or 2D.

Appropriate CAM software (you can also stock up with us) in conjunction with a rotary axis will allow you to perform machining in full 3D using 4 axes "from beginning to end" - by designing the appropriate model in the CAD program (also available from us), its import to CAM, where the user creates tool paths with the possibility of trajectory simulation and uploading to the control program with which we operate the machine.

Technical data:

- Control: CNC

- Working field : 600x900x80mm

- Table: T-shaped

- Movement in the axes: X, Y, Z

- Frame: welded steel

- Mounting method: clamps

- Engine type: Leadshine hybrid servo motors

- HIWIN trapezoidal linear guides

- Positioning accuracy: 0.03 / 300 mm

- Linear tool magazine (4 pcs.)

- ATC spindle - for automatic tool change

- Spindle power: 3 kW

- Spindle speed: max. 18,000 rpm

- Maximum feed speed: 15,000 mm / min

- Maximum working feed: 10,000 mm / min

- Collet: ER25 (3,175 / 4/6 / 12,7)

- Supported instructions: .nc, g-code

- Control system: DSP A57

- Power supply: 400V, 50 / 60Hz

- Working temperature: 0-45 degrees C

- Air humidity: 30% - 75%

The kit includes:

- milling machine with a movable gate

- ATC spindle 3 kW

- linear tool magazine (4 pcs.)

- tool height sensor

- inverter

- controller

- accessories

- tools

- a set of cutters

- spindle cooling pump

- cable set

- material holders

Optional equipment:

- Italian HSD spindle with ATC 4.5 kW

- vacuum table - we select and value suction pumps and systems for each table - client's side fans, vacuum pumps (also available from Becker).

- servo drives of the Japanese company Yaskawa and metal reducers on axles instead of belt transmission

- Z axis clearance 200/300/400/500 mm

- oil mist cooling the tool

- chip extraction

- Syntec, Siemens, Fanuc, NC Studio, ADTECH control system

- fourth rotary axis with tailstock

- driver for 4/5/6 axes

- a large wardrobe for a computer

- chip cover

- device installation

- scanning head

- switch cabinet with connection of peripheral devices

- CAM design software

- 3D modeling software

1 year warranty!

The ATMSolutions company specializes in individual orders. We implement projects in accordance with the client's guidelines. Please send all inquiries to: info@atmsolutions.pl, or using the "ASK QUESTION" function. We will respond as soon as possible.

The machine can be insured on preferential terms at PZU. Details from our Sales Specialists.

Depending on the selected machine control method, a PC (min.1.5Ghz CPU, 512MB RAM) equipped with the appropriate port (PCI, LPT or USB), a dedicated Windows system and control software may be needed for control.

CONSTRUCTION AND TECHNICAL PARAMETERS:

.- Control: CNC .

- Working area: 600x900x80mm

- Table: T-shaped .

- Motion in axes: X,Y,Z

- Frame: welded steel .

- Method of attachment: clamps .

- Motor type: hybrid servo motors by Leadshine .

- HIWIN trapezoidal linear guides .

- Positioning accuracy: 0.03/300 mm .

- Linear tool storage (4 pieces) .

- ATC spindle - enabling automatic tool change .

- Spindle power: 3 kW

- Spindle speed: 18,000 rpm max .

- Maximum feed rate: 15,000 mm/min

- Maximum working feed rate: 10,000 mm/min

- Clamping sleeve: ER25 (3,175/4/6/12.7) .

- Supported instructions: .nc, g-code .

- Control system: DSP A57

- Power supply: 400V, 50/60Hz .

- Operating temperature: 0-45 degrees C .

- Humidity: 30% - 75%