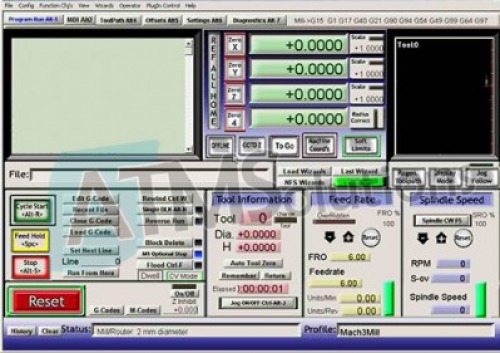

MACH3 PROGRAM

Mach3 is the most popular program for controlling CNC machines. The program allows simultaneous control of six axes. The software allows you to control any set of controller and engine, using a variety of drive transmission mechanisms: screws, toothed bars, belts, etc. Mach3 has the ability to separately define operating parameters for each separately. In the program window we have a current preview of the tool path, and we can control the machining parameters on an ongoing basis.

Mach3 allows you to control:

- CNC plotters

- milling machines

- CNC engraving machines

- lathes

- plasma burners

- Styrofoam cutters

- other CNC machines

Mach3 has the ability to independently expand the functionality through numerous macros available in the popular VisualBasic language. Thanks to this, it is possible to implement a large range of additional equipment, i.e. measuring probes, automatic tool length measurement systems, automatic tool magazines, etc.

The Mach 3 program is ideally suited to control our CNC devices.

Recommended hardware requirements:

- - Operating system version: Windows 2000, Windows XP, Windows Vista * or Windows 7 (64-bit versions for LPT port are not supported)

- - Processor:> 1Ghz

- - RAM memory: min 512MB

- - LPT or USB port

* Patch installation is required to install Mach 3 on 32-bit Windows Vista .

The price includes an individual license + program

!!! ATTENTION

We conduct training in the use of Mach 3 program and creating G-CODE for CNC machine tools. More information: info@atmsolutions.pl

!!! ATTENTION