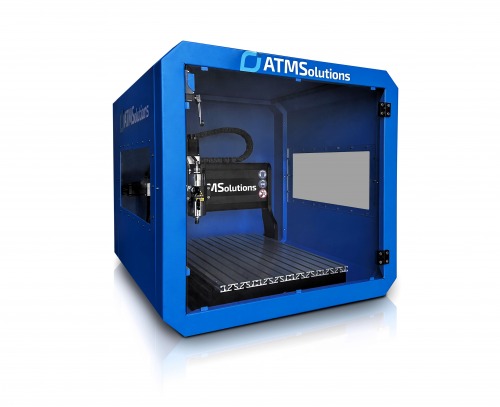

MILL PRO 60X90 1500W CNC MILLING MACHINE

The robust CNC milling machine with a working area of 600 x 900 x 130 [mm] has a positioning accuracy of 0.05 mm. It is distinguished by a reinforced structure, which significantly improves the machine's rigidity and effective linear drives on ball screws, which translates into machining speed . The milling machine is equipped with a tool height sensor which enables precise homing in the z axis and road connectors that control that the machine does not try to go outside the working area.

Mini CNC Milling Machine Pro 600x900x130 1500W will cope well with the processing of plastics, non-ferrous metals as well as the hardest aluminum alloys . It works well when making 2D and 3D surfaces, when milling, cutting and engraving even the most accurate details. The milling machine has the option of attaching a fourth rotary axis .

Construction: a movable gate with a through table (along the longitudinal axis we can place any long element), a T-table for convenient fastening of elements, ball screws (made in accuracy class C7, ground raceways), hardened linear guides and linear ball bearings .

Technical data:

- Device dimensions: 650 x 900 x 590 [mm] (XYZ)

- Workspace: 600 x 900 x 130 [mm] (XYZ)

- Feed in z axis: 100 [mm]

- Positioning accuracy: 0.05 mm

- Stepper drives: 3 A

- Set weight: 100 kg

The kit includes:

- strong mechanical construction

- three-phase brushless spindle, water-cooled, 1500 [W], 24000 rpm

- controller with a set of wires

- collets for 3.175 mm milling cutters and a set of HSS cutters

- tool height sensor

- water pump

- tool box

- mechanical limit switches

- Y-axis guide

- bath / cooling tool (mist or floodplain)

- milling machine housing

- vacuum table

- T-piece table from one element

- extractionchip

- DSP controller

- scanning head

- CAM design software

- control software

- 3D modeling software

- control cabinet with built-in computer

- swivel rotary axis (the so-called 5th axis)

- rotary fourth axis:

- 80 mm three-jaw self-centering chuck

- center height 65 mm

- clamping diameter 80 mm or smaller

- drive transmission: 6: 1, belt

- positioning accuracy: 0.3 °

1 year warranty !

The machine can be insured on preferential terms at PZU. Details from our Sales Specialists.

To operate the machine you need a PC (min 1.5Ghz CPU, 8GB RAM) equipped with a corei5 class processor, USB 3.0 port, Windows system and control software (recommended MACH 2, MACH 3).

CONSTRUCTION AND TECHNICAL PARAMETERS:

.- Dimensions of the unit: 650 x 900 x 590 [mm] (X Y Z) .

- Workspace: 600 x 900 x 130 [mm] (X Y Z)

- Z-axis feed: 100 [mm]

- Positioning accuracy: 0.05 mm

- Stepper drives: 3 A

- Set weight: 100 kg