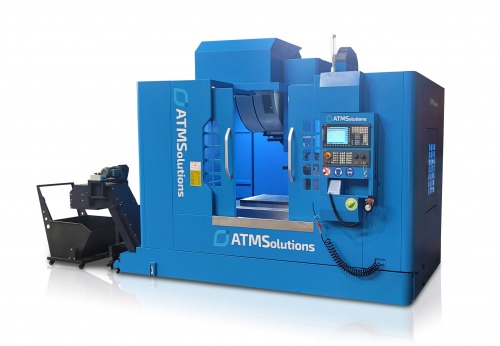

ATMS 700 VERTICAL MACHINING CENTER

The ATMS 700 machining center is a precise vertical machining center, created for the production of complex elements in various industries, starting from simple simple elements, forms, through the automotive industry, to such a precise industry as aviation.

Accuracy and precision of machining is ensured by:

- Bed construction with a cross table characterized by high rigidity.

- German Bosch-Rexroth or Japanese THK guides guaranteeing accurate machining.

- Accurate ball screws with pre-tensioned double C3 class nuts used in all axes are driven directly by servo motors. Direct drive transmission eliminates backlash and ensures high positioning accuracy.

- High-quality spindle that guarantees perfect precision throughout the entire speed range.

- Equipping the spindle with cooling ensures reliability of the machining process.

-Excellent reinforcement of the axis due to the design of the column in the shape of an inverted letter "Y".

-In order to achieve high positioning accuracy, the Z axis is equipped with a motor with enhanced power.

-The cast iron machine body ensures high stability and rigidity of the system.

The ATMSolutions product is designed for the greatest security. The tightly closed casing is designed to protect the operator from debris during machining, durable windows allow you to view the work area: control of tools and workpiece, processing progress, etc. Convenient operation of the work space is enabled by practical sliding doors.

Machine stability has been achieved by designing a large contact area between the bed and column.

Control over the ATMS machining center is provided by an external operator panel.

Additional auxiliary functions are implemented by specially designed pneumatic cylinders. The machining center has no hydraulic systems.

-All automatic functions are carried out mechanically or pneumatically

-Pneumatic tool clamping

The machine tool is equipped with a water gun for manual flushing of chips and a pneumatic gun for cleaning the processed material with air. All this will allow us to keep the machine clean and in good condition for many years.

Technical specifications

- CNC system Siemens 828D

- Work space:

-Work table dimensions: 800 x 420 [mm]

-T grooves (width / spacing / quantity): 14 x 80 x 5 [mm]

-Maximum table load: 500 kg

- Axis travel:

-X: 700 mm

-Y: 420 mm

-Z: 500 mm

- Spindle:

Spindle taper : BT40

-Maximum spindle speed: 8000 [r / min]

-Maximum cutting speed: 1 ÷ 10000 [ mm / min ]

justify; "> - Distance of the spindle taper from the table: 100 ÷ 600 [mm]-Spindle distance from the column: 480 mm

- Average spindle power (continuous operation): 11 kW

-Average spindle power (work for 30 minutes): 15 kW

-Spindle torque (permanent operation): 52.5 Nm

-Spindle torque (working for 30 minutes): 95.5 Nm

- Fast feed

-X: 36,000 mm / min

-Y: 36,000 mm / min

-Z: 30,000 mm / min

- Tool magazine:

- Tool magazine capacity: 20 pcs.

-Maximum tool weight: 8 kg

-Maximum tool length: 350 mm

-Maximum tool diameter: ?95 / ?125 [mm]

- Accuracy:

- Positioning accuracy (VDI / DGQ 3441): P 0.010 mm

- Positioning repeatability (VDI / DGQ 3441): Ps 0.008 mm

- Air pressure: 0.6 ÷ 0.8 [MPa]

- Machine weight: 4500 kg

- Machine dimensions (L × W × H): 3300 x 2700 x 2700 [mm]

- Power supply: AC 3?, 380 V, 50 Hz

- Power requirement: 20 kVA

Standard equipment

- Siemens 828D

- AICC II, Ethernet DNC, portable MPG room unit

- Threading function

- Fully closed housing

- BT40 Spindle speed 8000 rev / min

- External spindle cooling (without motor)

- Machining area lighting

- Three-color indicator light

- Heat exchanger

- Cooling system

- Chip conveyor with tank

- Transformer

- Automatic lubrication system

- Water gun

- Air gun

- Foundation blocks and fixing screws

- Auto power off function

- Tool box

- 20-piece tool magazine

- Door lock

- Automatic shut-off function

Optional equipment

- Mitsubishi M70

- Fanuc 0i MF

- 24-piece tool magazine

- Internal cooling of the spindle 20/30/70 [bar]

- AC electrical box

- Voltage stabilizer

- Heidenhain linear encoder

- TUV declaration

- Tool probe (RENISHAW TS27R)

- Workpiece probe (RENISHAW OMP60)

The machine is covered by a one-year warranty or for an additional 10% of the value of 2 years

In addition, ATMSolutions offers training in operating the machine and its software.

CONSTRUCTION AND TECHNICAL PARAMETERS:

.- Fanuc Oi MF CNC system (optional Mitsubishi M80A 15" LCD or Siemens 828D) .

- Workspace:

- Work table dimensions: 800x420 [mm]

- T-slots (width/spacing/number): 14x80x5 [mm]

- Maximum table load: 500 kg .

- Axis travel:

- X: 700 mm

- Y: 420 mm

- Z: 500 mm - Spindle:

- Spindle taper: BT40

- Maximum spindle speed: 10000 [rpm]

- Maximum cutting feed rate: 1 ÷ 10000 [mm/min]

- Spindle taper distance from table: 100 ÷ 600 [mm]

- Spindle distance from column: 480 mm

- Average spindle power (constant operation): 11 kW

- Average spindle power (maximum): 20.4 kW

- Spindle torque (fixed operation): 52.5 Nm

- Spindle torque (maximum): 130 Nm - Speed feed rate:

- X: 40,000 mm/min

- Y: 40,000 mm/min

- Z: 32,000 mm/min - Tool storage:

- Tool storage capacity: 24 units

- Maximum tool weight: 8 kg

- Maximum tool length: 300 mm

- Maximum tool diameter: Φ80/ Φ130 [mm] .

- Program resolution: 0.001 mm .

- Air pressure: 0.6 ÷ 0.8 [MPa] .

- Machine dimensions(L×W×H): 4215 x 3230 x 2700 [mm] .

- Power supply: AC 3Φ, 400 V, 50 Hz .

- Power requirement: 20 kVA

- Guarantee: 24 months .