LANTEK EXPERT DUCT

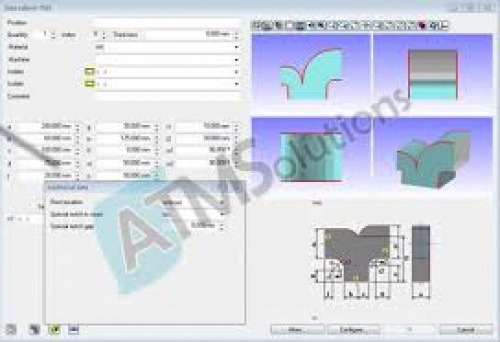

Lantek Expert Duct is software for calculating HVAC shapes and ventilation ducts used in heating, ventilation and air conditioning. Intuitive and easy to use software. The system has a built-in database of parametric elements that comply with DIN standards (squares, circles, cones, cylinders, boiler shapes, pipes, cross-sections, etc.) and cover most of the available channel shapes.

Software features:

- System based on the Microsoft SQL Express database,

- Licensed system based on USB hardware keys,

- Support for many machines (programming with laser, plasma, oxygen, water)

- Order explorer, order grouping (material, thickness, machine),

- 2D CAD - 2D design module,

- Automatic dimensioning of elements with reporting,

- Parametric shapes library,

- Import of DXF and DWG files, export of DXF / MEC files, import of elements from the machine code with verification and automatic recognition of contours,

- Geometry verification and error correction,

- Automatic, semi-automatic and manual nesting (nesting of elements on sheets) together with reports - orders and elements, drawing numbers, identifiers, nesting visualization, number of pieces required / on sheet / missing, production time and costs, material with use and usable waste ( percentage / area / weight), other,

- nesting explorer,

- Support for multiple burners (nesting based on multiple burners) for one and many sheets,

- Cutting into a common line,

- Nesting on more sheets simultaneously, nesting optimization,

- Processing (automatic or manual) depending on the technology (Water, Plasma, Oxygen, Laser),

- Advanced input and output options,

- Automatic checking of the correctness of entries and exits,

- Additional cutting technologies (bridges, micro bridges, cutting head height control, automatic cutting continuation, loops),

- Automatic and manual determination of the cutting order,

- Element database,

- Material database,

- Automatic and manual waste creation, creation of cutting lines taking into account technology (input / output), many types of cutting lines depending on needs, rounding of the cutting line, the possibility of cutting waste into smaller elements,

- Automatic nesting on waste,

- Materials management - management of the commercial sheets warehouse and useful waste,

- Set of reports,

- Communication with MS Excel,

- Automatic calculation of component surfaces, weight, weight and machining time and costs,

- Library of parametric ventilation and sewage elements compliant with DIN standards (channels, arches, floors, passages, branches, etc.)

- Intuitiveness and ease of entering data (it is enough for the user to choose the shape and enter the parameters, and the system will generate the element itself),

- Automatic splitting of items exceeding the sheet size,

- Element management. All elements are stored in the database,

- Weight, time and cost calculation,

- Flexible configuration of bookmarks and connections,

- forming lines,

- Automatic creation of steering wheels,

- Vents,

- Reports for the ventilation industry (valuations, labels, etc.).