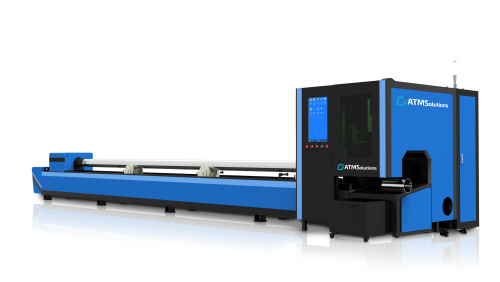

FIBER ATMS LASER CUTTER FOR PIPES AND PROFILES 6M MAX 6KW

Laser cutting machine ATMS with FIBER technologyDedicated to rotary machining during one process. It allows for shape cutting of rectangular and circular pipes and profiles, as well as cutting of various types of shape grooves.It is a perfect solution for manufacturing plants, for which the functionality of the machine and complete utilization of its capabilities counts.

Used mainly in heavy industry, in manufacturing plants, and wherever long-term, trouble-free operation is required. Incredibly stable, the design of the support frame together with the reinforced table ensures precise cutting leveling any deformation. Disturbances from the environment are isolated, and internal vibrations are absorbed by the structure, ensuring perfect guidance of the laser beam.

The laser cutter uses proven components and control software directly from reputable manufacturers. The head design allows the operator to easily perform basic maintenance. The laser beam feed from the resonator to the cutting head is realized by means of a suitable optical fiber made and arranged in the machine structure so that it is maintenance-free and does not require maintenance or inspection. The fiber-optic cable supplying the beam from the resonator to the head is equipped with a safety circuit to prevent operation of the machine in case of damage.

The design ensures operator safety, and the intuitive operator panel allows for convenient and comfortable operation.

The control system provides, among other things:

.- .

- .

the ability to engrave lettering on cut details using a laser beam,

. -

automatic height adjustment system for the cutting head nozzle,

. -

implementation of protection of the head against collision with the workpiece (e.g., in the case of incorrect alignment of the workpiece being cut).

Thanks to the FIBER laser, the cutting edge is smooth and left without burrs. Since additional edge processing is unnecessary, this saves considerable time. The device is equipped with a professional system that ensures stable and reliable guidance of the light beam along with its control.The high quality of the laser beam generator guarantees its service life of up to more than 100,000 hours.

.Advanced laser technology goes hand in hand here with the ease of operation of the machine. The machine is ideal for industrial operation. It is mainly designed for processing steel, primarily stainless steel and carbon steel.

The software is compatible with many CAD formats, energy consumption has been reduced, while keeping process stability high, ensuring easy maintenance and low cost of ownership.

.The ATMSolutions company is dedicated to personalizing equipment and technology solutions according to individual customer needs. We have extensive experience, which we have developed during many implementations. It is possible to customize the device.

CONSTRUCTION AND TECHNICAL PARAMETERS:

.- .

CNC control

. -

Maximum profile length: 6,000 [mm]

. -

Working speed: 100 m/min

-

Maximum profile dimensions: 20 - 220 [mm]

. -

Laser source:

. -

Source type: FIBER

. -

Laser power: 6 kW

. -

Manufacturer of resonator: MAX Photonics

-

Resonator cooling method: radiator

. -

Positioning accuracy of the head: 0.01 mm

-

Cutting head:

. -

Manufacturer: Raytools

. -

Cutting head equipped with:

. -

Distance (capacitive) sensors, providing constant, rapid measurement of the distance of the head with respect to the workpiece, whose task is also to prevent collision of the head (so-called anti-collision system) with the workpiece (e.g., in case of incorrect alignment of the workpiece being cut)

- Cutting head equipped with:

- Cutting head equipped with:

-

calibration of the nozzle height adjustment system is performed automatically

. -

Drives:

. -

The axes are equipped with Yaskawa servo drives

. -

View of working field:

. -

By means of a certified safety glass

. -

camera vision system

. -

Intelligent features:

. -

Perforation technology

. -

Automatic inspection of tubes and profiles

. -

Autofocus

. -

Automatic O2 pressure control

. -

Active anti-collision function of the laser head

. -

Automatic lubrication system for linear guides

. -

Flycut

. -

Possibility to interrupt the cutting process, make appropriate adjustments, and then continue work

. -

Humidity of room air: not more than 80%

. -

Operating temperature range: from 15ºC to 35ºC

. -

Machine supply voltage: 3x400V 50Hz

Standard equipment:

.-

Machine suitable for machining tubes and profiles

. -

Auto Raytools head

. -

Control system - installed control software with dedicated display and controller (hand-held remote control/transmitter to control machine movements)

-

Autofocus allowing automatic adjustment of the head distance from the material

. -

Servo motors: Yaskawa

. -

Industrial liquid cooler for FIBER laser cooling

. -

Automatic pipe/profile sporter

. -

Pipe / profile clamp

. -

Wireless controller

. -

Extraction system

. -

Controls

. -

Voltage stabilizer

. -

Wire set

. -

Cutting time simulator for individual projects

. -

Set of nozzles and protective lenses

.