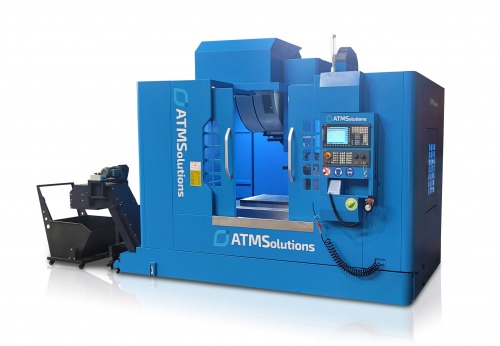

VERTICAL MACHINING CENTER ATMS 1100

The machining center ATMS 1100 is a high-precision vertical machining center, created for the production of complex parts in various industries, starting from simple simple parts, molds, through the automotive industry, to such a precise industry as aviation.

Accuracy and precision are provided by :

.- Highly efficient spindle cooling system dissipates heat for high accuracy, and effectively extends spindle life .

- High-quality guideways help achieve the highest possible machining accuracy, and their abrasion resistance allows the machine to last a long time .

- Cross-table bed design characterized by high rigidity .

- The most important parts of the machine are made of high quality cast iron to ensure the rigidity and quality of the machine .

- The machine tool is equipped with a water gun for manual flushing of chips and a pneumatic gun for cleaning the workpiece with air. All this will allow us to keep the machine tool clean and in good condition for many years .

ATMSolutions offers training on the machine and its software.

CONSTRUCTION AND TECHNICAL PARAMETERS:

.- CNC system: FANUC Oi MF

- X-axis travel: 1100 mm

- Y-axis travel: 600 mm .

- Z-axis travel: 600 mm .

- Table dimensions: 1200x600 mm .

- T-slots(number / width / distance): 5x18x100 mm

- Max. table load capacity: 1000 kg

- Spindle taper: BT40 .

- Spindle speed, standard: 8000r/min .

- Distance from spindle to table: 120-720mm .

- Distance from spindle to column guard: 650 mm

- Spindle motor power: 11/15 KW

- Speed feed rate in X / Y axis: 36,000 mm/min

- Speed travel in Z-axis: 30,000 mm/min .

- Max. working feed rate: 1-10,000 mm/min

- Motor power on X / Y / Z axis: 3 x 3 x 3 kW .

- Tool storage: 24 pcs

- Max. tool weight: 8 kg

- Max. tool length: 300 mm

- Max. tool diameter: Φ120 mm

- Voltage/frequency: 400 V /50 Hz

- Dimensions: approx. 3300x2400x3000 mm .

- Weight: approx. 6300 kg .

Standard equipment:

.- FANUC Oi MF .

- MPG

- Tool storage .

- Spindle speed of 8000 rpm .

- Cooling system .

- Automatic lubrication system .

- Spindle cooling .

- Cabinet .

- Water gun .

- Pneumatic gun .

- Signal lamp in 3 colors .

- Cab lighting .

- Automatic power off .

- Tool kit, .