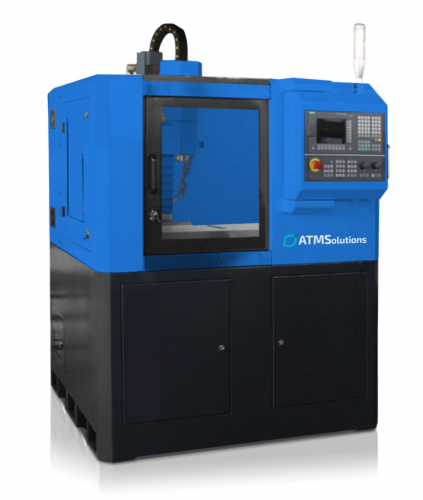

CNC MACHINING CENTER ATMS COMPACT 310X200 ATC

The CNC machining center ATMS Compact 310x200 ATC is a device thatós useful not only in workshops, but also in production plants, where there is a need to relieve the load of larger machines. Due to its small size and compact design, it is also ideal for use in schools, universities and other educational centers as a device for teaching purposes.

Mainóve features of the machine:

- Solid machine design characterized by high rigidity .

- Ball screws guaranteeing rotation stability and precision .

- High-quality components from renowned brands .

- Central lubrication system .

- Stiff and precise work station .

- Cooling system

- Automatic tool changing system .

- Small size and weight of the machine .

- Compact design .

The machine uses a high-end spindle thatós capable of excellent rpm precision within its speed range. Thanks to the use of top-quality guideways, the ATMS Rotary Center has high rigidity and high positioning resolution. The previously mentioned elements, combined with an appropriate design, guarantee excellent quality of the rotaryóbeat.

Implemented software from a renowned, well-known and well-respected brand in the market provides the highest comfort of work and simple operation. The product was created with the utmost security in mind. Thoroughly enclosed housing is designed to protect the operator during rotation. Sturdy glass panes allow you to view the work area, the progress of machiningóbing, inspect the tools and the material being machined.

All documentation, including technical and operating documentation, is supplied with the machine.

Technical data:

.- Control system: SIEMENS 808D ADVANCED .

- Total power: 5.5 [kW] .

- Spindle power: 2.2 [kW]

- Coolant pump power: 95 [W]

- Maximum torque in X/Y/Z axes: 3.5/6/6 [Nm] .

Spindle:

- Spindle taper: BT30 .

- Spindle speed: 10,000 [rpm] .

- Spindle distance from column: 280 [mm] .

Tool storage:

- Storage capacity: 8 [units] .

- Maximum tool diameter: 70 [mm] .

- Maximum tool weight: 6 [kg]

- Tool change time: approx. 6 [s] .

Work table:

- Dimensions: 690 x 210 [mm] .

- Distance of table surface from spindle: 90-390 [mm]

- T-slots (width/distance/quantity): 16 [mm]/63 [mm]/3 [pcs] .

- Maximum load capacity: 100 [kg] .

Slide:

- X-axis travel: 310 [mm]

- Y-axis travel: 200 [mm] .

- Z-axis travel: 300 [mm] .

- Speed travel in X, Y, Z axes: 10,000 [mm/min] .

Dimensions:

- General dimensions: approx. 1800 x 1640 x 2000 [mm] .

- Weight: approx. 1500 [kg] .

- LCD display: 8.4 [inches] .

- Tank capacity: 50 [l] .

Operating environment:

.- Recommended ambient temperature: 15-35 [°C] .

- Humidity: 30 ÷ 75 [%] .

- Power supply: 400 [V] / 50 [Hz] 3 phases .

Standard equipment:

- Workspace enclosure .

- Hand control remote control .

- Cooling system

- Central lubrication system .

- E-stop button .

- LED lamp .

Optional equipment:

- Change control system to Fanuc .

- Tool measuring system .

- Part measurement system .

- Change to Fanuc