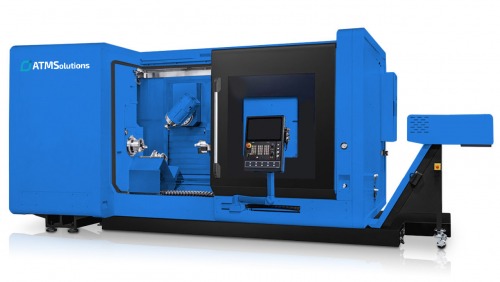

TURNING AND MILLING CENTER FOR SIMULTANEOUS 5-AXIS MACHINING, WITH MILLING HEAD (B AXIS) AND TWO TURNING SPINDLES

The Lathe & Milling Center is an ideal solution for the production of highly precise and complex partsó. Thanks to the device's ability to work comfortably and the combination of precision and ergonomics, our device is indispensable where high quality and fast production are required. It is used, among others: in the automotive industry, aerospace industry and many other fields requiring high precision.

The machine uses a high-end, high-powered spindle thatós capable of excellent precision rpm in its speed range. Thanks to the use of top-quality guides, the center has high rigidity and high positioning resolution. The previously mentioned elements, combined with an appropriate design, guarantee excellent quality of the rotaryóbeat.

Implemented software from a reputable, well-known and well-respected brand in the market ensures the highest comfort of work and simple operation.

The machine tool is equipped with a water gun for manually rinsing the wiórów and a pneumatic gun for cleaning the workpiece with air. All this will allow us to keep the machine tool clean and in good condition for many years.

The above-mentioned features translate into increased production efficiency while maintaining the product parameters required by the customer. This makes the machine satisfy the most demanding operatorsów.

All documentation, including technical and operating documentation and system manual, is supplied with the machine.

Possibility to configure the device according to individual customer preferences.

Technical data:

.- Turning diameter: ø 500 [mm] .

- distance between spindle faces: 1,500 [mm] .

- Turning length: 1,200 [mm]

- Turning passage of each turning spindle: ø 100 [mm] .

- tip of each turning spindle: A2-8 .

- chuck on spindle: type KNCS, diameter ø325 [mm] .

- max. speed of each turning spindle: 4,000 [rpm] .

- max. power of main turning spindle (100%): 30 [kW] .

- max. power of turning counter-spindle (100%): 25[ kW] .

- max. torque of main turning spindle (100%): 650[ Nm] .

- max. torque of turning counter-spindle (100%): 300 [Nm] .

- travel in Y axis: 120[mm] + 120 [mm] .

- Z-axis travel: 1,200 [mm] .

- C axis with brake: on both turning spindles, .

- B axis working range: 120 [degrees] to +120 [degrees] .

- fast travel in X, Z axes: 30 [m/min] .

- fast passes in Y axis: 10 [m/min] .

- measuring lines in axes: X and Y and Z,

- lubrication system: central .

- chip conveyor: hinged .

- working space of machine tool: fully enclosed, with roof, prepared for connecting mist filtration from coolant .

- oil mist separation: coolant mist separator .

- max. speed of the milling spindle: 12,000 [rpm] .

- max. power of milling spindle: 29 [kW] (100%), .

- max. milling spindle torque: 86 [Nm] (100%), .

- tool storage: 40 pcs

- max. tool length: 320 [mm]

- spindle taper: CAPTO C6

- control, SIEMENS 840 SL with 3D simulation .

- touch liquid crystal monitor: 22 inches

- dialog programming overlay: SHOPTURN

- Tool wear monitoring: broken or worn tool monitoring system: automatic during machining .

- Tapping: without compensating toolholder .

- Machining programming on the face of the turned part: TRANSMIT function .

- transforming the curve on the roll face: function TRACYL .

- vibration elimination: by continuously changing the speed .

- horse function: realized by counter-spindle .

- residual material removal function: automatic .

- border gear milling function: „gear hobbing” .

- - turning: classic and eccentric .

- - import of workpiece drawing into control: DXF import .

- - import and storage of user files: convenient preview of own .pdf files in the control .

- - machine tool documentation: integrated in the control .

- - remote access: „from” and „to” machine tool from external PC .

- kinematics setting cycle: of the machine tool with the workpiece measuring probe .

- USB connector: 1 pc .

- RJ45 connector: 1 pc .

- machine part touch probe: RENISHAW RMP60

- tool probe – dual (laser + tactile) BLUM .

- additional hand control wheel: electronic .

- machine door: automatic opening/closing .

- preparation for automation: interface for robot connection .

- max. coolant cooling pressure through the tool: 80 bar

- cooling system: 950 liters with filter belt and gun, and space flushing

- processing coolant, control cabinet air conditioning .

- 3D model of machine tool workspace: for integration into CAM system .

- Total machine tool shutdown under defined conditions: automatic .

- automatic sleep of the machine tool: for „standby” mode.

- control and documentation: in Polish .