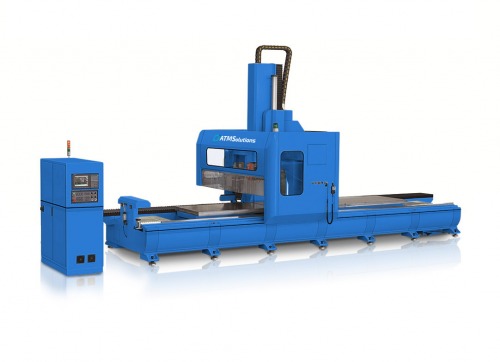

ATMS 5-AXIS CNC MACHINING CENTER FOR 5000-5 PROFILES

The ATMS 5000-5 CNC Cutting & Machining Center is a high-quality 5-axis cutting & machining centeróoffering a wide range of work performed, such as drilling, milling, threading, cutting, etc. It is used in the production of structural elementsóof doors, windows and other similar productsómade of light metal alloys.

The 5-axis machiningób capability offers the possibility of machining a given material from several sides during a single clamping, resulting in high versatility and efficiency of the machine. The 12 kW 5-axis high-powered spindle has an automatic tool changing function. It is perfect for multi-plane machining.

The machine is distinguished by a large working area, which allows for the processing of workpiecesós size. A movable gantry moving along the workpiece allows convenient control of the spindle position. The tool magazine allows the previously mentioned processesós to be performed during one cycle. This streamlines the work process and reduces operator involvement by automating the machiningób process.

High accuracy of the performed partsós is ensured by selected components. The device is characterized by a massive structure, high-quality spindle, servo motors, rigid guides and components from renowned manufacturersós. The CNC control system allows for simple importing of the machiningós data. The controller has an intuitive interface, whichóry provides comfort of work and allows setting dedicated parametersóbwork. The structure of the system allows for convenient operation and easy handling of the device. Thanks to its quality and reliability, the above device will satisfy the expectations of the most demanding operatorsów.

.

Main features of the device:

- Stiff and stable construction for high accuracy of the performed elements .

- Intuitive CNC system for easy and clear operation, perfect for 5-axis machining

- High-power multi-axis spindle .

- Tool storage .

- The device is additionally equipped with a saw for cutting .

- Wide range of machining capabilities .

- A set of tools that allows you to make a variety of types of rings .

- Safety and work order .

- High-quality components .

- Automatic lubrication system .

All documentation, including technical and operating documentation and a system manual, is supplied with the device.

Technical parameters:

- Control system: SYNTEC

- Work table size: 5000x1000 [mm]

- Axis travel X, Y, Z: 5000/400/600 [mm] .

- Speed of X, Y, Z axes: 50/30/30m/ [min] .

- Tool storage: 8+8

- Spindle power: 12 [kW]

- Tool holder type: HSK F63

- Maximum spindle speed: 18,000/24,000 [rpm]

- Maximum spindle speed.

- Greasing: automatic

.- Operating temperature: 15 - 35 [?]

- Operating humidity: 15 - 35 [%] .

- Operating pressure: 0.6~0.8MPa .

- General machine dimension: about 8500x3000x3000 [mm] .

- Weight: approx. 9000 [kg] .

- Power supply: 400 [V], 50 [Hz], 3 phases .

.