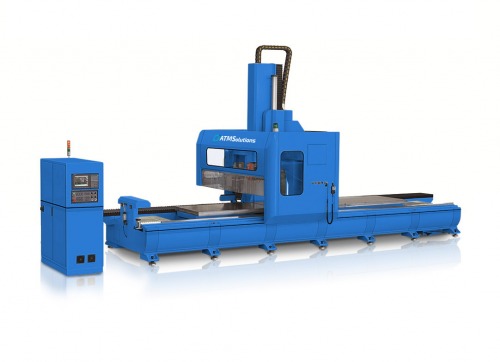

ATMS 4-AXIS CNC MACHINING CENTER FOR PROFILES 7000-4

The ATMS 7000-4 4-axis CNC Turning Center is a high quality 4-axis center designed for the machiningós of aluminum, light metals, and wood and metal compositesós commonly used in the production of structural componentsós of doors, windows, gardensós and other similar productsós made of light metal alloys.

The machine is distinguished by its large working area, which makes it possible to machine partsóbout large size. A movable gantry moving along the workpiece allows you to conveniently control the position of the spindle. Characteristic of the machine is the range of work performed, as the machine allows you to perform many typesóof machining such as drilling, threading, beveling, milling, etc. The automated work process and tool storage allows to perform the previously mentioned processesów during one cycle.

High accuracy of the performed elementsós is ensured by selected components. The device is characterized by a massive structure, high-quality spindle, servo motors, rigid guides and components from renowned manufacturersós. The CNC control system allows for easy importing of the machiningós data. The controller has an intuitive interface, whichóry provides comfort of work and allows setting dedicated parametersóbwork. The structure of the system allows for convenient operation and easy handling of the device. Thanks to its quality and reliability, the above device will satisfy the expectations of the most demanding operatorsów.

Mainóve features of the device:

.- Stiff and stable construction for high accuracy of the performed elements .

- Intuitive CNC system interface for easy and clear operation

- Possibility to work on several parts .

- High quality components from renowned brands .

- Automatic lubrication system .

- Tool storage facilities .

- High power spindle .

- Tool set to ensure the performance of various types of machining .

.

All documentation, including technical and operating documentation and system manual, is supplied with the device.

Technical parameters:

- Control system: CNC

- X-axis travel: 7000 [mm] .

- Y-axis travel: 500 [mm] .

- Z-axis travel: 350 [mm] .

- Feed rate: X: 50 [m/min] , Y: 25 [m/min], Z: 10 [m/min] .

- Tool storage: 8+8

- Spindle power: 9.5 [kW]

- Spindle speed: 24,000 [rpm]

- Maximum spindle torque: 6.4 [Nm] .

- Maximum tool length: 100 [mm]

- Drives: Yaskawa servo motors .

- Slides: Hiwin

- Greasing: automatic .

- Cooling: Oil mist .

- Operating pressure: 0.6-0.8 [MPa] .

- Operating temperature: 15 - 35 [?]

- Humidity: 15 - 35 [%] .

- Power supply: 400 [V], 50 [Hz], 3 phases .

- Weight: approx. 5900 [kg] .

- Total dimension: approx. 10000x2230x3060 [mm] .