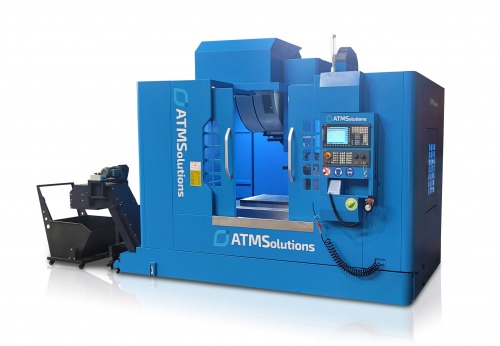

ATMS 900X240 MACHINING CENTER

The ATMS Circulation Center is the ideal solution for the production of high-precision and complex partsó. Thanks to the device's ability to work efficiently and the combination of precision and ergonomics, our device is indispensable where high quality and fast production are required. It is used, among others: in the automotive industry, aerospace industry and in many other fields requiring high precision.

The machine uses a high-end, high-powered spindle thatós capable of excellent precision rpm in its speed range. Thanks to the use of top-quality guideways, the ATMS Defense Center has high rigidity and high positioning resolution. The previously mentioned elements, combined with an appropriate design, guarantee excellent quality of the obróbki.

The machine is equipped with an Automatic Tool Changing system, so it can perfectly handle such types of machining as milling, planning, chamfering, drilling, reaming without the need for worker intervention during machining.

Implemented software (it is possible to select the system according to the customer's preferences), provides the highest comfort of work and simple operation.

The ATMSolutions product is designed with the utmost security in mind. The enclosed housing is designed to protect the operator from shrapnel during machining, and the highly durable glass allows observation of the process being performed.

The machine tool is equipped with a water gun for manually flushing the wiórós and a pneumatic gun for cleaning the workpiece with air. All this will allow us to keep the machine tool clean and in good condition for many years.

The above-mentioned features translate into increased production efficiency while maintaining the product parameters required by the customer. This makes the machine satisfy the most demanding operatorsów.

Mainóve features of the machine:

- rigid and stable workstationótestifying to the high quality of workmanship,

- linear guides that guarantee high accuracy of rotation,

- massive machine body,

- sturdy and rigid construction,

- precise guides,

- high accuracy of positioning,

- high quality spindle that guarantees excellent precision over the entire speed range.

Included:

.- control system with display, .

- swivel (fourth axis), .

- USB port, .

- threading function, .

- built-in internal memory, .

- driveów controllers, .

- electrical cabinet, .

- high-capacity workstation, .

- high-power spindle, .

- automatic lubrication system, .

- workspace lighting, .

- water spray gun, .

- pistol pneumatic, .

- workspace enclosure, .

- plumbing for compressed air connection, .

All documentation, including technical and operating documentation and system manual, is supplied with the device.

Possibility to configure the device according to individual customer preferences.

Technical parameters:

.- Controller: Siemens 808D .

- Table dimensions (length x width): 900 x 240 [mm] .

- T-slots (number x width x spacing): 3x12x78 [mm]

- Maximum table load capacity: 200 [kg] .

- X-axis travel: 500 [mm]

- Y-axis travel: 260 [mm] .

- Z-axis travel: 400 [mm] .

- Distance of spindle end to work table: 120-500 [mm]

- Distance of spindle axis to column surface: 300 [mm]

- Spindle taper: BT40/120 .

- Spindle drive: belt transmission .

- Maximum spindle speed: 6,000 [RPM]

- Motor power: 5.5 [kW]

- X-axis torque: 6 [Nm] .

- Y-axis torque: 6 [Nm] .

- Z-axis torque: 11 [Nm] .

- Speed feed rate: 8 [m/min] .

- Tool storage (BT40): 12 [pcs] .

- Air demand: ≥6.5 [kg/cm2] .

- Power supply of the device: 3x400[V]/50[Hz]

- Operating temperature: 15-35 [°C]

- Humidity: 10-30 [%] .

- Machine weight: approximately 1,700 [kg] .

- Dimensions of the machine tool(L x W x H): approx. 2000 x 1850 x 2350 [mm] .

.