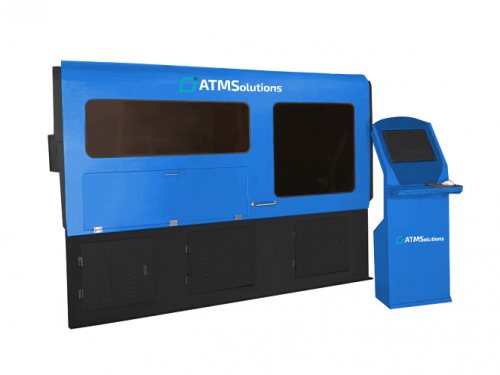

AUTOMATIC WIRE BENDING MACHINE ATMS 2D EXPERT

The automatic numerically controlled bending machine designed for wire bending is an excellent solution for companies in the construction industry, but also not only. The device allows repetitive bending of complex shapesós. The configuration provides an automatic process of making the shape thanks to the use of an advanced control that allows importing graphic filesów.

.The base of the machine is a rigid structure, which, combined with reliable mechanical workmanship, guarantees stable and reliable operation. The machine is equipped with a servo type drive, so precision and speed of operation are ensured.

Numerical control allows the machine to be operated from the operating panel. Adapted controller to ensure automation of the system, it allows to process many typesós of wire shapesós selecting the appropriate process parameters.

The applied design solutions, as well as high-end components, make the machines dedicated to high-performance and repeatable wire bending processing.

All documentation, including technical and operating documentation and system manual, is supplied with the machine.

Technical data:

.- Wire diameter: 3-8 [mm] .

- Control: dedicated numerically controlled controller .

- Import of graphic files possible .

- Motor types - servo .

- Motor powers: .

- Wire feeding motor power 4.5 [kW] .

- Wire bending motor power 3.8 [kW] .

- Cutting motor power 1.5 [kW] .

- Maximum wire feeding speed: 90 [m/min] .

- Dimensions: approx. 2500 x 1050 x 1750 [mm] .

- Equipment weight: approx. 1250 [kg] .

- Feeder: 1000 kg of wire .

- Weight of feeder: approx. 400 [kg] .

- Power supply: 3-phase, 400 [V], 50 [Hz] .

- Operating environment - temperature: 15 ÷ 35 [°C] .

- Operating environment - humidity: 30 ÷ 75 [%] .