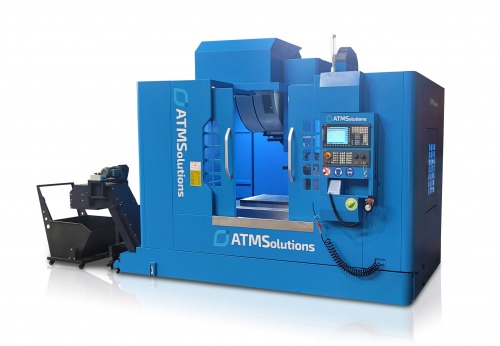

ATMS 1300X700 MACHINING CENTER

Vertical machining centers by ATMSolutions have been created for the production of components in a wide range of industries, starting from simple parts, molds, through complex components for the automotive industry, and ending with such a precise industry as aviation.

.Dedicated to advanced manufacturing tasks, the ATMSolutions vertical machining center is equipped with an industrial numerical control installed in the operator panel. Advanced technology, operator-friendly software allow to automate and increase the efficiency and reduce the cost of the manufacturing process. ATMSolutions machining centers allow to perform machining of simple and complex details.

The machine is equipped with an Automatic Tool Changing system, so it can perfectly cope with such types of machining as milling, planning, drilling, reaming without the need for worker intervention during machining.

The ATMSolutions machining center is designed with the utmost safety in mind. The carefully sealed enclosure is designed to protect the operator from debris during the machiningóbing process, and the high-strength glass allows observation of the process being performed.

The machine tool is equipped with a water gun for manually rinsing the wiórs and a pneumatic gun for cleaning the workpiece with air. All this will allow us to keep the machine tool clean and in good condition for many years.

The above-mentioned features translate into increased production efficiency while maintaining the productós parameters required by the customer, which makes the machine satisfy the most demanding customersów and operatorsów.

All documentation, including technical and operating documentation and system manual, is supplied with the device.

Possibility to configure the device according to individual customer preferences.

Technical parameters:

.- Control system: Siemens

- Table dimensions: 1300 x 700 [mm] .

- Permissible load: 1,200 [kg]

- T-slots: 18x5x110 [mm] .

- Distance of spindle axis from guide surface: 740 [mm]

- Distance of spindle tip from table surface: 110 - 810 [mm] .

- Automatic tool changing system: 24 [pcs]

- Axis drives: servo type .

- X-axis motion range: 1,300 [mm] .

- Y-axis range of motion: 700 [mm] .

- Z axis range of motion: 700 [mm] .

- Power of X/Y,/Z axis drive: 3/3/3.5 [kW] .

- Maximum working feed rate: 10,000 [mm/min]

- Speed feed rate in X,Y,Z axis: 24,000 [mm/min] .

- Spindle taper: BT-40 .

- Spindle power: 11/15 [kW]

- Spindle speed: 10,000 [rpm]

- Machine weight: approximately 11,000 [kg] .

- Machine dimensions: approx. 3,600 x 3,200 x 3,000 [mm] .

- Operating temperature: approx. 15 - 35 [?] .

- Humidity: approx. 10 - 30 [%] .

- Power supply: 400 [V], 50 [Hz], 3-phase .

Included:

.- Servo motors, .

- Control of X, Y, Z axes, .

- Stiff and stable construction, .

- Work area housing, .

- Spindle including belt type transmission, .

- Ball screw and linear guides of reputable brands .

- Electrical components .

- Coolant reservoir, .

- Automatic Tool Changing System .

- Chip flush gun, .

- Electrical cabinet, .

- Guideway lubrication system, .

- LED lamp for illuminating the work area, .

- Toolbox, .