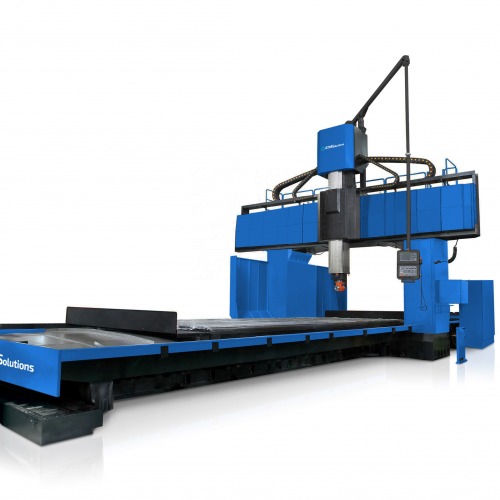

ATMS 5000X3000 GATEWAY CENTER

The ATMS Gantry Center is an ideal solution for industrial metalworkingóing. It is used in many manufacturing processes, such as: precision componentsóing building structures, gas and steam turbine blades, engineós bodies for the power industry, drivesós, etc.

Thanks to the implementation of a high-power spindle and a wide range of working field, the machine can easily cope with the machiningób of steel, for example. Suitable dimensions and high rigidity of the structure allow to apply optimal parametersóbing. Movement in the axes is carried out on precision-ground guides, whichóre provide adequate vibration dampening and guarantee the desired lifting capacity with the appropriate smoothness and tolerance.

The equipment is equipped with a precision horizontal milling head. It guarantees a 360-degree rotation aroundóthe C-axis. which significantly expands the application spectrum of the device while maintaining the desired rigidity and rotating power of the machine.

The ATMS Gate Center uses software from a renowned and well-known and respected brand on the market, which ensures the highest comfort of work, while providing simple operation.

The above-mentioned features translate into increased production efficiency while maintaining the productós parameters required by the customer, which makes the machine satisfy the most demanding customersów and operatorsów.

All documentation, including technical and operating documentation and system manual, is supplied with the device.

Possibility to configure the device according to individual customer preferences.

The set includes:

.- Horizontal milling head with 360-degree rotation .

- Automatic tool changing system .

- Cooling and oil distribution system .

- Essential pneumatic and hydraulic components .

- Control cabinet .

- Safety guard .

- Workspace lighting .

- Chip conveyor .

- Set of necessary tools .

Technical parameters:

- Mitsubishi M80A control system .

- Working table dimensions: 5,000 x 3,000 [mm] .

- Permissible table load: 18,000 [kg] .

- X-axis range of motion: 5,200 [mm]

- Y-axis range of motion: 3,200 [mm]

- Z-axis range of motion: 800 [mm] .

- Range of rotation around C axis: 360 [degrees]

- Distance between spindle and table surface: 200 - 1,000 [mm] .

- Distance between columns: 3,400 [mm]

- T-slots: 13 x 28 x 200 [mm] .

- Feed rate: 10,000 [mm/min]

- X-axis rapid feed rate: 10,000 [mm/min]

- Speed feed rate in Y/Z axis: 15,000 [mm/min] .

- Spindle cone: BT-50 .

- Max spindle speed: 6,000 [rpm]

- Spindle power: 15 [kW]

- Tool storage capacity: 32 [pcs]

- Storage operating automatically .

- Tool diameter: 125 [mm] .

- Max tool length: 400 [mm]

- Maximum tool length.

- Max. tool weight: 20 [kg]

- Machine weight: 55 [t]

- Power supply: 400 [V], 50 [Hz], 3-phase .

- Operating temperature: 15 - 35 [?]

- Humidity: 10 - 30 [%] .