Metallic and ceramic CO2 tubes are now very common in the laser plotterós market. These tubes are much better in terms of manufacturing design than classic glass CO2 tubes, resulting in longer life and reliability. Metal and ceramic CO2 (RF - Radio Frequency) tubes operate at a very high frequency reaching up to 100kHz, so they are also much more accurate than glass CO2 tubes, which is of great importance for precise cutting and engraving of materialsóat high speeds. The size of the spot obtained from them after focusing the beam reaches a size of about even 0.05 mm.

Figure 1. Synrad metal CO2 tube. [1]

Figure 1. Synrad metal CO2 tube. [1]

Figure 2. Iradion ceramic CO2 tube. [1]

Figure 2. Iradion ceramic CO2 tube. [1]

.

In metal and ceramic CO2 tubes, the laser beam is produced by excitation of gas moleculesóinside. The gas mixtureór consists primarily of carbon dioxide, helium, nitrogen, waterór. Carbon dioxide makes up about 5% of the mixture. It is this that forms the actual laser beam. Stimulated by the RF pulse, the nitrogen atoms transfer energy to the carbon dioxide molecules, which causes them to emit photonsów. The vast majority of the mixture consists of helium molecules (about 90% of the mixture). Helium's job is to maintain a low temperature inside the tube. This gas is the most difficult to maintain because its molecules can penetrate the walls of a tightly sealed tube.

Thus, the degree of sealing of CO2 tubes is a key parameter characterizing their durability and reliability, whichóra allows them to maintain constant power during continuous operation. Absolute tube sealing is impossible to achieve based on basic materials. The chemical reaction of the gas mixtureówith someómaterials and the prevailing high temperature inside the tube furthermore significantly limit the range of materialóselection.

Compared metal and ceramic CO2 tubes

.Until recently, glass and metal were the only materials thatór used for CO2 laser tubes. A third option is the relatively recently introduced ceramic-core tubes. The design solutions and the material used make them superior to metal tubes. The differences between metal and ceramic tubes are described below. While there are many companies on the market that produce both metal and ceramic tubes, ATMSolutions offers tubes from twoól leading companies: Synrad (metal tubes) and Iradion (ceramic tubes)

.The difference between metal and ceramic tubes, as the name suggests, is in the material from which they are constructed. The main problem with the reliability of metal-tube lasersóis that metal is reactive with the gas mixtureós. After a long time, free oxygen molecules react with this exposed metal, oxidation occurs, whichóre causing changes in the original composition of the gasów mixture, which can translate into a decrease in the effectiveness of the tube and its shorter life.

The metal structure is welded, which can already introduce leaks to some extent. In addition, the construction uses O-ring seals for sealing, whichóre worn out over time in reaction with the environment (moisture, temperature changes). All of this allows air and moisture to enter the laser tube, and gas particlesów outside.

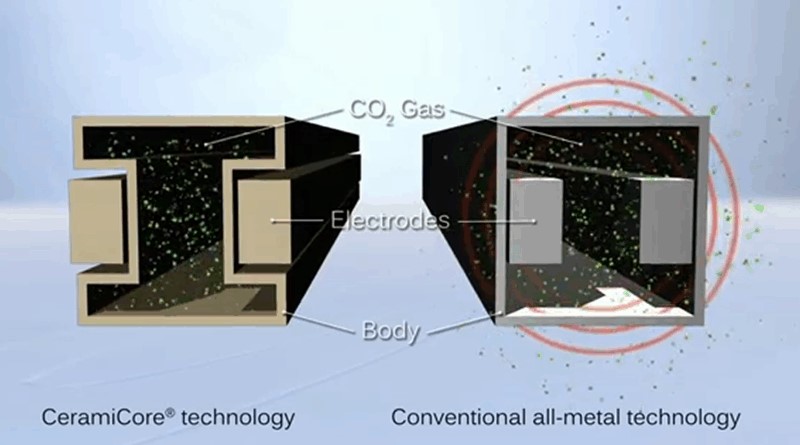

These problems have been solved in ceramic CO2 tubes. The developed technology involves separating the electrodes that excite the gas particles outside the laser tube (Fig. 3). All reactive components are placed in the core having only contact with pure ceramic - aluminum oxide (Al2O3). Due to itsóy chemical composition, aluminum oxide is a very good material because it does not react chemically with the gasów mixture.

Figure 3. Structural solution of ceramic and metal CO2 tubes. [2]

.

Properties of alumina Al2O3:

.- very high operating temperature, up to 1700°C, .

- high hardness and abrasion resistance, .

- can be machined with high precision and polished, .

- resistant to corrosion and chemical influences,

- resistant to corrosion and chemical influences.

- relatively low density, .

- very high dimensional stability, .

The ceramics are fired at very high temperatures, which further ensures that all organic impurities generated during the production of the laser tube are burned off eliminating interference with the composition of the mixture at the outset.

The coefficient of thermal expansion of aluminum oxide is 8.4x10-6 /°C and this is almost 3 times lower than the expansion of aluminum of 23.1x10-6/°C. Thermal changes affect the stability of laser operation. Therefore, based on the thermal expansion parameters, ceramic tubes show better operating stability compared to metal tubes. The ceramic core can operate at a higher pressure of the gas mixtureów. The higher pressure generates a better operating frequency. Increasing the switching frequency (rise and fall time) further increases the range of maximum engraving speeds. In addition, ceramic tubes consume about 30% less energy in their operation than metal tubes.

.

Table 1. Properties of metal and ceramic CO2 tubes.

.|

Tube type . |

Metal RF (manufacturer – Synrad) . |

Ceramic RF (manufacturer – Iradion) |

|

Life span |

20,000 ÷ 35,000 |

~30% longer than a metal tube |

|

Can be regenerated . |

possible |

possible |

|

Cooling . |

Air (for power up to 100W), for higher power liquid |

Air (for powers up to 100W), for higher powers liquid |

|

Minimum spot diameter [mm] . |

~0.05 |

~ 0.05 |

|

Pulse generation time |

< 100 |

< 75 |

|

Construction of workmanship |

Welded metal construction with electrodes inside |

Ceramic structure fused with electrodes on the exterior |

The data in the table above are approximate and may differ from the actual parametersótub CO2.

.

Based on the information gathered, it can be seen that ceramic tubes, which are relatively new on the market, have better properties than metal tubes. It is also worth remembering that both metal and ceramic tubes have significantly better performance than glass tubes. Rós parameters differences between glass and metal tubes are significantly greater than between metal and ceramic tubes, which causes a continuous increase in sales of metal and ceramic tubes.

Resources:

[1] https://atmsolutions.pl/

[2] https://www.iradionlaser.com/en/technology/our-technology/

[3] https://www.synrad.com/resources/general_information/aboutco2lasers

[4] http://stjorsen.pl/rightbar/ceramika-techniczna/materialy