In the current era of the ever-increasing encroachment of so-called Industry 4.0, it is rather difficult to imagine a manufacturing company that does not have a numerically controlled machine in its machinery park. This is due to the fact that production is constantly increasing, reducing the time for making given parts the accuracy of their manufacture and, of course, much more. Of course, conventional machines are still present in many plants while they are not the core of production, but are only auxiliary to production, most often in unit production, where the time of arming the machine in relation to CNC machines is definitely shorter.

Numerically controlled CNC machines allow the production of much more complex details, with detailed geometries in relation to conventional machines and in relation to other manufacturing techniques such as casting, etc. In the case of CNC machines, it's important to remember that it's not the construction of the machine itself that is responsible for the capabilities given to us by such a machining center –

of course, the construction affects the rigidity of the machine, cutting speeds, and even the construction defines the number of axes available on the machine – however, it's the control through which we can perform all the machining movements of the machine that really defines what we can do on a given milling machine or lathe.

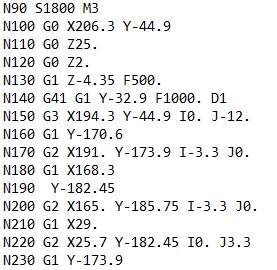

Before poring over the most popular control systems available on the market, it is necessary to explain what the control is responsible for and what working with the control looks like. The most important thing you need to know when dealing with cnc controls, whether Sinumerik or Fanuc, is the ability to program in ISO g code language. ISO programming language means programming machine movements by creating a code built from movements described by parameters X,Y,Z(possibly additionally A,B,C which correspond to the spindle/table angular position in case of multi-axis machines) and corresponding so-called G-codes and M-codes.

(sample g-code in ISO – sourceóown source)

.Familiarity with such program writing is important because the vast majority of CNC machines are based on such a reading of the programs controlling the machine, where the exception may be Heidenhain because it uses a slightly text-modified form of code,but the programming principle itself is identical. The ability to program from the level of the controller is very desirable especially in companies where, for example, make parts with fairly simple geometries, or do not use software supporting the process CAM manufacturing. Basically, most of the controls have quite well-developed functions of programming in ISO mode, differing from each other mainly by more or less developed text editor – for example, Heidenhain has a very good text editor allowing you to find characters quickly replace all misassigned values in the whole code, e.g. for feeds which allows you to quickly edit the code in case of mistakes.

.

(sample code from Heidenhain&ndash control; own source)

.

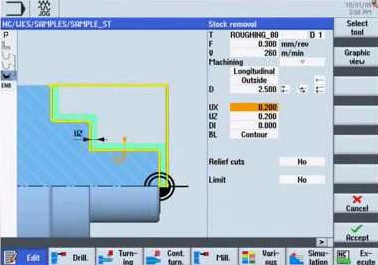

While discussing the modesóof operation on the given controls, it is necessary to remember about the second type of programming which is no longer the same as writing programsóline by line, but more like describing and filling in the data about the geometry we want to mill/bore, with what speeds, feeds, rotations. The detailed data filled in this way allows the machine to generate a ready program for the part, which automatically includes all the coordinates of the tool path, its corrections, feeds, etc. This programming mode is much faster than the previously described line-by-line programming, it is easier to catch mistakes in it, and it is much easier and faster to edit. Such machine functions which re behind the with the help of data entered by the programmer generate us ready code is called cycles. Many controls offer such cycles, most repeatable on different controls however described according to the taste of the manufacturer controls.

(Sinumerik system with shopturn overlay – contour turning cycle source:https://www.youtube.com/watch?v=it4pa1wLdR4 )

.Cycles are extremely helpful, many companies rely solely on programming and operating machines using cycles because they completely meet expectations and needs. For example a very well-developed, quite simple to use and having most of the necessary functions is a programming overlay from Siemens: Shopmill – milling, Shopturn – turning.

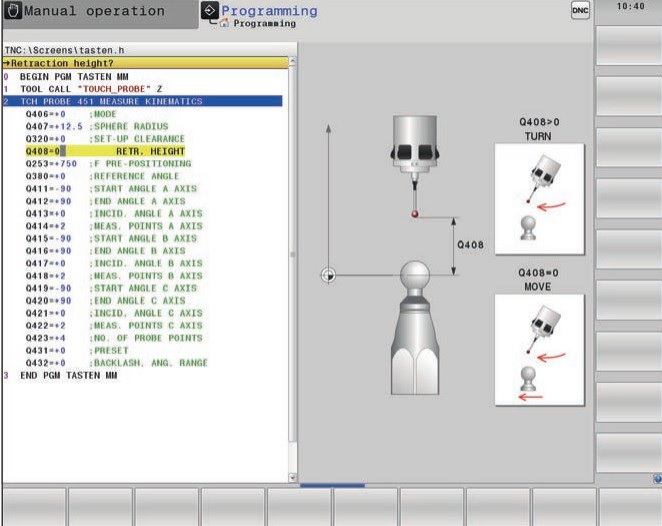

It is worth remembering that cycles correspond mainly to flat geometries of the creation of rotations of flat geometries. Only a handful of controls have the ability to program 3D(Heidenhain) rotations however, even for an experienced operator or programmer, these can be time-consuming operations to perform. It should also be remembered that working on a CNC machine is not only based on creating machining programs, but also on complete equipping the machine before starting machining, i.e. measuring tools, basing the workpiece in the machine space. If you have a probe for measuring tool length and diameter, as well as a probe for measuring the workpiece, any measuring cycles available on the controller will be extremely helpful. With the help of measuring cycles it is possible, for example, to base the workpiece in the hole, completing at least the diameter of the hole itself, and at that moment the machine plays us the probe control program automatically. The issue of availability of machining and measuring cycles is extremely important when deciding on the control of the machine, so you need to think very carefully about the given solutions in relation to the requirements of the machine.

(Heidenhain TNC640 – cycle probe calibration, source:https://www.heidenhain.pl/fileadmin/pdb/media/img/892916-2A_TNC640_HSCI_en.pdf )

The third method of programming is programming using CAM software. This method consists in creating a picture of a part on the basis of which a toolpath is created, from which the final result of the work –g code is then generated, ready to be loaded into the memory of the machine. Such programming allows virtually 100% utilization of the machine's potential,

thanks to the possibility of creating extremely complex rotationsós interrupted 3D geometries,and also multi-axis programming. Often without CAM software, it would be impossible to create a program on the machine for certain parts, especially those with irregular shapes, where manufacturing precision, surface quality, etc. counts a lot. Often such programs have

many thousands of lines of code which is impossible to achieve by the methods discussed earlier. In order to take full advantage of CAM software it is extremely important to configure, postprocessor suitable for a given control. A postprocessor is more or less a tool that translates CAM software into a language understood by the controller on a given machine. Therefore, it is very important to precisely configure and implement such a postprocessor so that it generates the right code that does not cause collisions, corresponds to what the machine understands, etc.

(ZW3D CAM software – sourceósource: https://zw3d.com.pl/rodowisko-projektowe/ )

Having in mind the cited schematic mode of operation on CNC controls can be spróbated be guided by certain aspects when choosing the right controls for the machine. You still need to remember that some are possible to be used on machines from different manufacturers The three most popular controls are Fanuc, Sinumerik, Heidenhain. They can be used for

many machines, while it is worth remembering that Fanuc is based on programming in ISO mode, does not have as extensive rotary cycles as the aforementioned Sinumerik or Heidenhain,is most often found in mass production, where the share of writing new programs is much smaller than in unit production. The automotive industry is an industry that often uses

Fanuc control. It is worth remembering that Fanuc is also a leading manufacturer of robotsów industrial,so in series production,adapting the control and, for example, the robot operating the lathe of the same company is much easier.

(Fanuc 0i control panel : https://www.youtube.com/watch?v=h_kjFQCCxbw )

..

On the other hand, Sinumerik as a Siemens control and Heidenhain control are controls more specialized, having a large set&of functions and parameters thanks to which it is possible to create more complex programs for more complicated geometries.The

Sinumerik does a great job as a lathe control, handling lathes with driven tools, Y-axis, part pickup or complicated operations capturing the workpiece by the counter-spindle without any problems. On the other hand, the Heidenhain control performs very well with all kinds of milling rotations, supports multi-axis rotations, and has a very well-developed probe cycle module.

When choosing a control, it is also worthwhile to be guided by the technical background of the company providing the control, the level of qualification of the employees the possibility of any training and technical support in case of problems.