Fiber optic technology

.The Fiber laser is a laser in whichóthe active medium is an integrated fiberód doped with elements such as erbium, ytterbium, neodymium, dysprosium, praseodymium and thulium, unlike conventional lasersóin which the beam is transported outward and guided by an optical system. Comparedóing with other laser technologies, fiber lasers provide many advantages, such as ease of use, high reliability and quality of work. With the help of a fiber-optic core, laser light of a certain wavelength can pass through the fiber. The input power needs to be high enough to ensure adequate output power. Fiber lasers have a number of advantages. They are very efficient, reliable and stable compared to other types of lasersów. These lasers provide high beam quality while being compact, mobile and easy to use. They provide high optical and electrical performance and are resistant to changing environmental conditions, which translates into low maintenance costs. Fiber lasers have many applications, such as cutting, and marking metal materialsós. They are used in many industries such as automotive, medical, electronics and manufacturing.

Figure 1. Effect of changing marking parametersóon surface quality. (Sourceósource ATMSolutions)

..

The most common fiber optic sources include:

.MOPA

.The MOPA laser, as a particularól type of Fiber laser, with a wavelength of 1064 nm, has the ability to mark, etch and engrave productsóre for a variety of industries thatóre used for identification, personalization or decoration. The term MOPA is actually an abbreviationótem for Master Oscillator Power Amplifier. This type of technology makes it possible to achieve an efficient laser system by manipulating power and bandwidth.

In this type of fiber optic source, the change of laser power is done with a separate fiber amplifier (power amplifier), whichóry scales the signal from the mainów low-power narrow-spectrum oscillator (master oscillator). The MOPA excels at reducing unwanted nonlinear effectsóre that can produce other wavelengths or reduce beam power.

In this technology, the pół diodes are used as the pumping mechanism and the fiberód as the beam-guiding, amplifying medium and as the resonator.

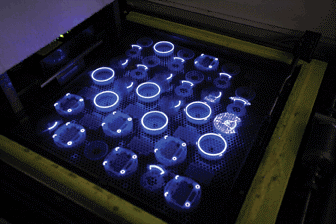

Figure 2: MOPA marking machine. (https://www.fiberlabs.com/)

.

The MOPA is a good solution for color marking of stainless steel and black and white marking of white plastics and white and black plastics.

Figure 3. Capabilities of the MOPA marking machine. (Sourceósource ATMSolutions)

.

GREEN

Green laser is a laser beam with a wavelength of 532 nm generated by a high-powered multifunctional diode laser pump. In this wayób the laser beam itself is generated at double the frequency (two photons of the same frequency interact with a nonlinear material resulting in a photon with twice the energy of the initial photons (i.e., twice the frequency and half the wavelength)). With the combination of matched phases and input laser beam, we can finally obtain a beam with high power and intensity. After that, the beam path is automatically changed by controlling the tilt of the galvanometer or precision moving station.

The green laser beam working device has good working stability and low maintenance cost. It is particularlyólly used for engraving glass, artificial crystal, acrylic glass and other transparent materialsóas well as for tródimensional engraving of these materials. It is great for two- and trójdimensional engraving of crystalsóbased on photos, personalized giftsóor decorative products.

Figure 4. Two- and tróy-dimensional engraving. (sourceóown source)

..

UV

UV laser markers use a laser source with a wavelength of 355 nm and frequency doubling technology. Compared with the infrared laser beam, the UV laser has a smaller beam cross-section and therefore can significantly reduce the mechanical deformation of the workpiece during marking.

The UV laser is mainly used for accurate marking or engraving. It can be used for food marking, marking medical packaging, micro holesóing or cutting silicon wafers.

The main advantages of the UV laser are high beam quality, small cross-section of the focused laser beam, precise marking, higher resolution, small heat affected zone or no deformation of the material to be marked.

.

Figure 5. Examples of UV marking. (sourceóown source)

..

Figure 5. UV laser used for lithography (sourceósource: https://www.photonics.com/Articles/Lasers_for_Lithography)

SUMMARY

.Today, the use of Fiber Optic Markers is becoming increasingly popular in the market. Their main advantages are high working speeds and a wide range of materials that can be processed. In addition, the mobility of the devices and the intuitiveness of the controlós programs often affect the ease of use of marking machines.

Fiber-optic marking machines are mainly used for marking and engraving of materialsód for plaques, nameplates, medals, statuettes, souvenirs, etc. Increasingly, all plaques made of metallic materialsós or coated metals are processed with Fiber Markers, thanks to which in a short time we are able to achieve high quality engraving resistant to abrasion. With this marking machine we can cut thin films or engrave some plastics.

.In the souvenir industry especiallyólly often used sourceód Green when marking in glass, acrylic glass or crystal. Thanks to this technology, we are successfully able to surface mark and create trójdimensional graphics (often based on photos).

A great use of innovative technology is the use of UV Marker for marking food or medical packaging. This allows for hygienic, non-contact processingób. Additional popular uses of this sourceód are cutting silicon wafers, making micro holesów or a wide range of applications in lithography.

The table below shows the sourcesód and their general applications.

|

Family . |

Wavelength |

Application |

Material . |

|

Fiber |

1064 nm |

labeling, engraving, cutting (thin films) |

metals, coated metals, plastics, mirror |

|

MOPA |

color marking, engraving |

metals, stainless steel, plastics |

|

|

Green |

532 nm |

engraving |

glass, crystal, acrylic glass |

|

UV |

355 nm |

marking, engraving |

plastics, silicon, ceramics, coated glass |

Resources:

[1] https://atmsolutions.pl/

[2] https://www.researchgate.net/publication/276024952_Fiber_Lasers

[3] https://www.rp-photonics.com/frequency_doubling.html

[4] https://www.arcalabelingmarking.com/prodotti/laser-markers/mopa-fiber-laser-laser-marking/

[5] https://www.spilasers.com/industrial-fiber-lasers/how-fiber-lasers-work/

[6] https://www.fiberlabs.com/glossary/fiber-laser/