Check out the available configurations

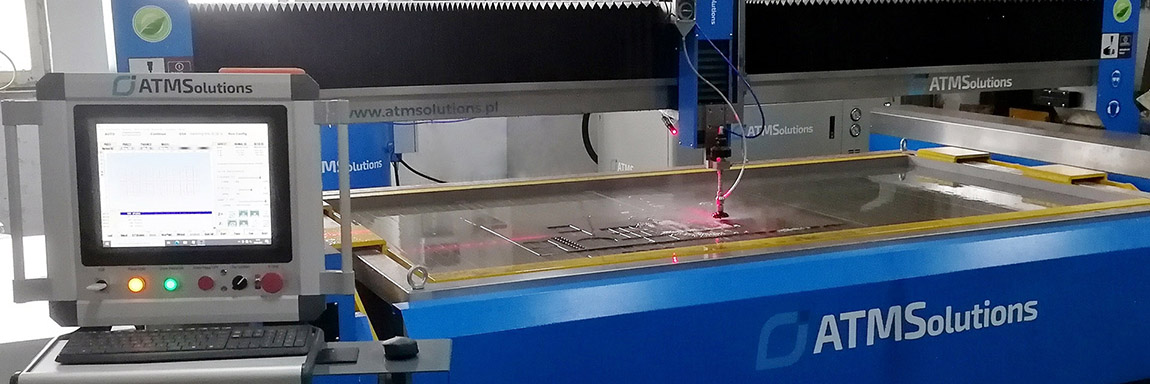

ATMS Waterjet Cutting Machines - a new dimension of machining!

.

A versatile, multi-tasking industrial machine for professionalsó

Particularly valued for its ability to work with materials of varying thicknesses and difficult to machine without changing tools.

CUTTING PRECISION - RELIABILITY of use - MATERIAL VERSATILITY

.The ATMS waterjet cutting machines are a combination of high quality and precision of cutting and efficiency due to the use of modern waterjet cutting technology. The machine with industrial numerical control, adapted to work in any working area and with materials characterized by different hardness and thickness - up to 200 mm.

The versatility of the machine is confirmed by the ability to cut a wide range of materialsów!

.

The device allows you to cut materialsó such as steel, titanium, dibond, aluminum, and natural stone. In addition, it is great for cutting brittle materialsós such as glass and ceramics, as well as plastics, sponges, foams, many typesós of compositesós, and even foodós products.

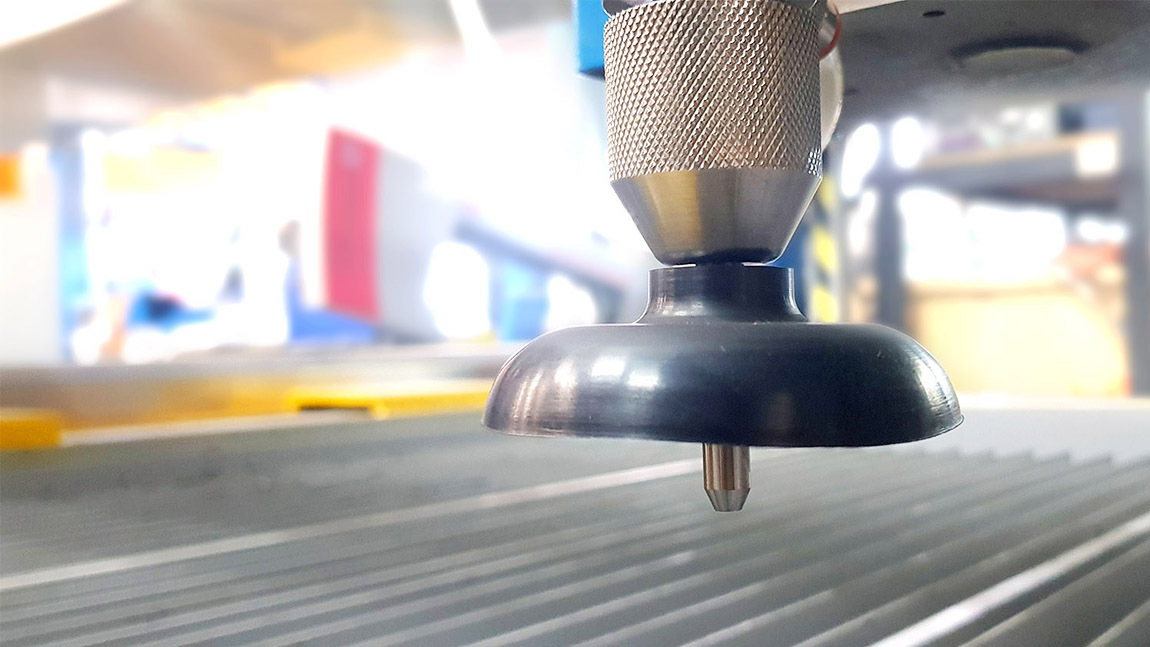

Cutting materialsós so different in hardness and cutting any designed shapeós possible thanks to the machine's incredibly powerful water pump. The pump makes it possible to achieve high pressures and thus extreme water speeds at the head outlet (up to 4000 km/h). The use in the cutting process of a material supporting the cutting process - the so-called abrasive, which is mixed with water in the mixing chamber, allows to increase the range of hardness and thickness of cut materialsó

.

How does the ATMSolutions WaterJet work?

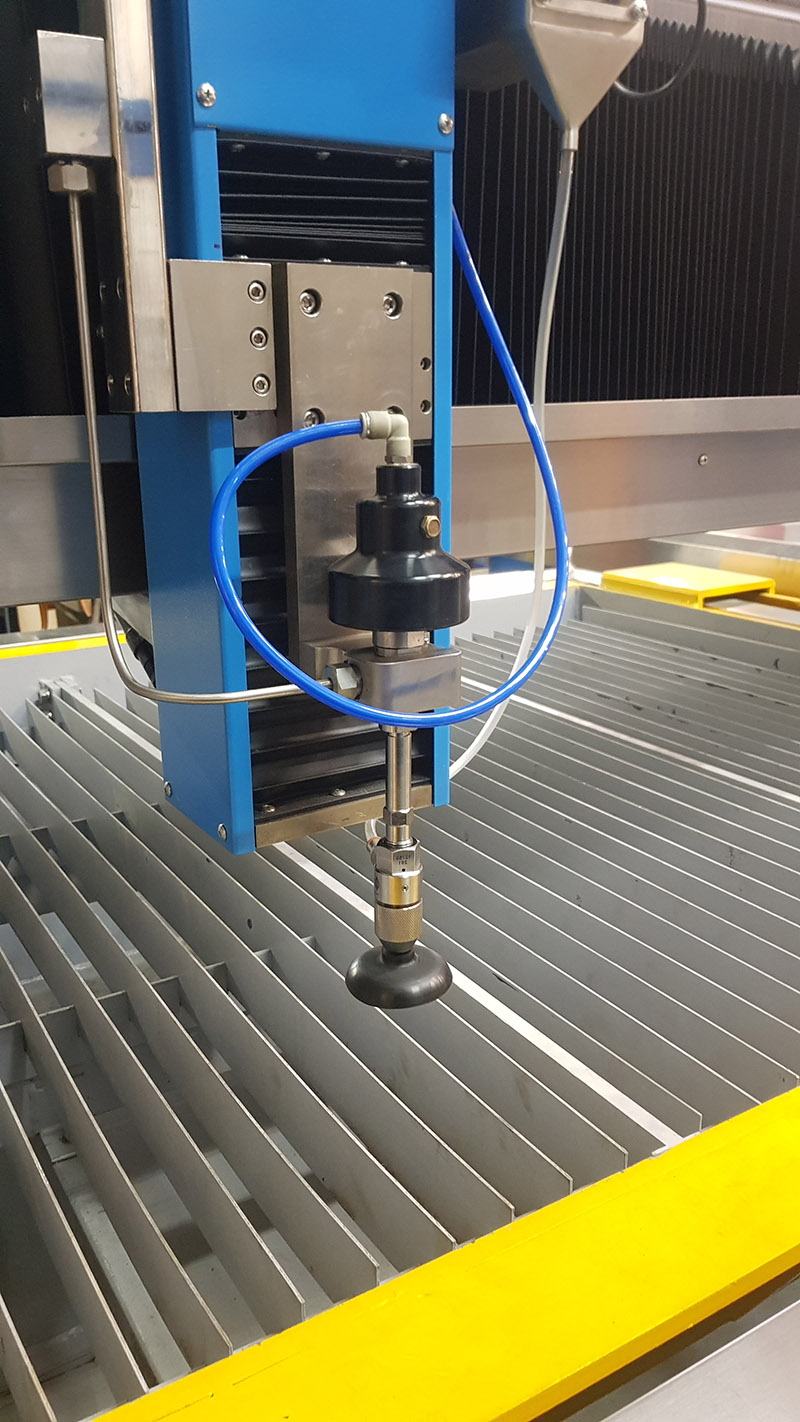

.It's easy! Precision cutting is the precise movement of the cutting head of the ATMS Waterjet Cutting Machine, ensured by top-of-the-line components including servo drives and linear guides. The integrated, intuitive CAD/CAM system allows you to work with a variety of file formatsów, create a design directly in the control software, or produce a geometrically complex detail without the need for an external computer.

The ATMS water cutter for cutting hard materialsów both thin and thick uses a stream of water with a high pressure (up to 420Mpa) with an abrasive thatós accelerated to high speeds. Abrasive – natural crystal - allows to achieve appropriate cutting speeds and guarantees obtaining a workpiece with high surface quality, without burrsós. Cutting occurs at room temperature without causing structural changes in the material.

The machine is equipped with a water treatment system, and can operate in a closed water circuit, reducing water consumption. The use of the machine does not require the use of chemicals, so no harmful fumes or smoke are produced, making the work safe for the operator and the environment.

Numerically-controlled WaterJet ATMS waterjet cutting machines work in the automotive, aerospace, glass, and stone industries, among others, to produce parts with high accuracy and high quality surface finish.

MACHINE ATTRIBUTES

.- material versatility .

- ease of operation thanks to intuitive software .

- possibility to cut through almost any material .

- high cutting precision and ideal cutting surface quality .

- received workpieces do not require further processing of the cut surface .

- thickness of cut materialós depends only on its hardness .

- possibility of using a 5-axis head .

- positioning accuracy up to 0.02 mm .

- environmentally safe .

The WaterJet Water Cutting Machine by ATMSolutions comes in many configurations of working areasómm from 500x500 mm to 6000x12000 mm, and in twoóseries that differ in design.

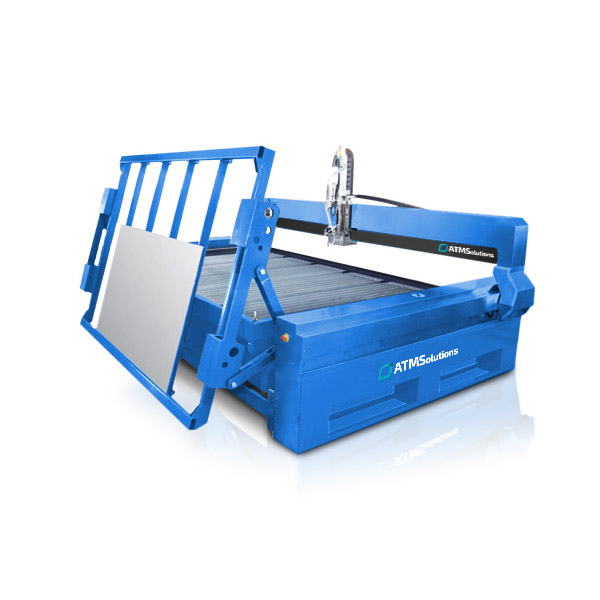

The FA series is a portal design. The single-arm counterbalanced gantry allows quick loading and unloading of any material to be processed on the machine.

The B series is a timeless gantry design. A classic machine design for modern businesses.

A multitude and variety of machine-compatible accessoriesós allow you to customize the machine for future advanced production tasks. ATMSolutions also manufactures custom cutters according to individual design.

.

Deciding on a WaterJet ATMS delivers along with its expertise:

.- Cutting machine in portal or gantry design .

- Durable, knife-edge materialós cutting station .

- Operator station to operate 3-6 axes .

- CAD/CAM software license .

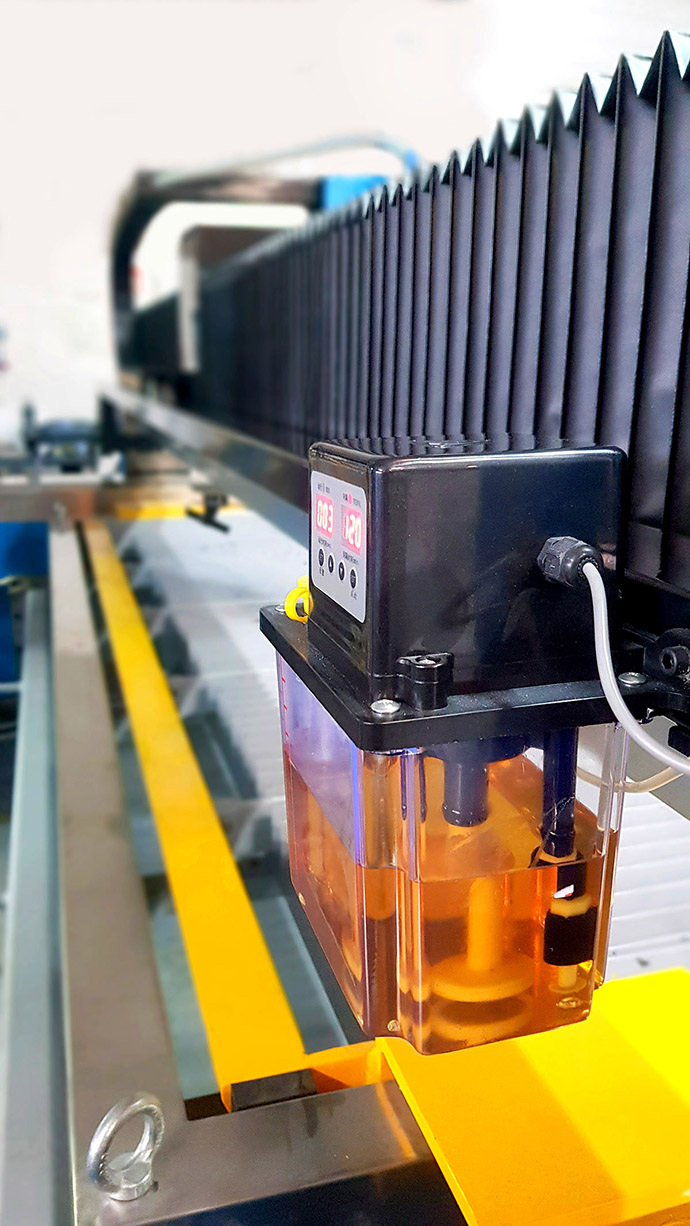

- Centralized lubrication system .

- High-pressure booster system .

- Fan oil cooling system .

- Automatic abrasive feeding system 100l, 200l or 1t .

- System Water treatment with filters

- Garnnet starter kit .

- Pack of consumable parts for one year .

- Guarantee directly from the manufacturer ATMSolutions! .