The INDUSTRIAL series is the ideal solution for the production of high-precision and complex parts in both plastics and other materials. Thanks to the combination of precision and ergonomics, our machine is indispensable where high quality and fast production are required. It is used, among others: in the furniture, machinery, automotive, aerospace and many other industries.

The basic feature of the Industrial series is the possibility of almost any expansion according to individual customer requirements.

.

By working with reputable suppliers in the field of components for the CNC industry, efficient and easy-to-use solutions have been developed, allowing maximum optimization of the time and cost of production of a component.

There is the option of implementing multi-axis controls and realizing additional axes in almost any form - rotary adapters, tilting axes, setting axes with angle units, oscillating knives, drilling units and many others.

Machines are made from the highest quality materials and components. This is especially important for the manufacture of parts with high accuracy requirements and wherever the repeatability of a component is a key and desirable feature.

The machines are made from the highest quality materials and components.

What distinguishes the Industrial Series milling plotters?

.- highest quality components that guarantee efficient operation, even under high loads, and above all account for the long life of the device, including heads and spindles from reputable manufacturers such as Hiteco or HSD, .

- large possibilities of retrofitting the machine with special machining equipment according to individual expectations - adapting the machine fully to individual customer requirements, including drilling units, oscillating units, angle units, .

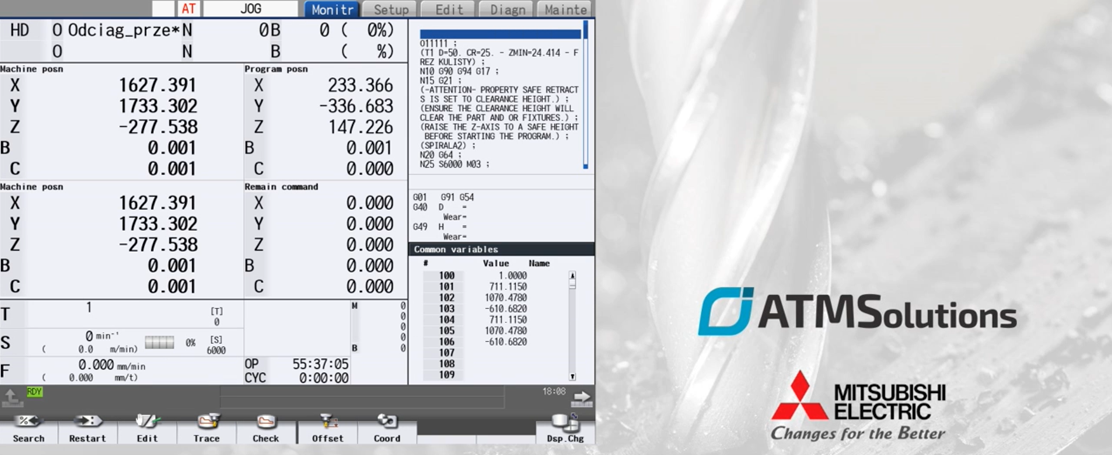

- industrial controls, including Mitsubishi Electric brand, where by using a single control system for the entire machining cell, we have the possibility to retrofit the machine with additional equipment in the future, .

- production of a dedicated work area, according to the individual needs of the customer, .

- intelligent nesting modules - extremely useful when working with cutting material. They reduce processing time by reducing the costs associated with cutting and keep waste to a minimum.

We equip plotters with an Automatic Tool Changing system, which allows the machine to keep running while machining, without having to stop the machine to change the toolholder.

Standardly installed are linear tool magazines with the possibility of increasing the capacity according to individual needs. We also have the option of installing turret magazines, which are equipped with high-precision servo motors - providing faster tool changes compared to standard linear magazines.

The machine can also be equipped with a turret magazine, which is equipped with high-precision servo motors - providing faster tool changes compared to standard linear magazines.

Industrial series milling plotters are equipped with Mitsubishi Electric brand controls and drives, among others.

Collaboration with Mitsubishi Electric ensures that we are compatible with the entire hardware of the CNC machines we manufacture, from the control cabinet equipment, to kinematics components such as drive motors, to control logic components.

In plotters, we use a single control system for the entire machining cell. This makes it possible to retrofit the machine with additional equipment (including industrial robots) in the future.

Mitsubishi Electric is a world leader in the supply of controllers and servo drives for the production of CNC machine tools. The use of their solutions in the machines we manufacture translates into real benefits, such as reduced production times, streamlined ordering and logistics, electronic and system compatibility, increased safety and machining precision, or the ability to integrate with automated production lines.

Mitsubishi Electric is the world's leading supplier of controllers and servo drives for CNC machine tools.

Through the use of components from a single manufacturer, we are able to fully exploit the potential of a given machine and monitor parameters from the user interface. This definitely affects the ease and degree of optimization of the machine kinematics and, as a result, translates into precision and speed of machining. This generates real savings for the user.

In the Industrial series it is possible to implement multi-axis controls and realize additional axes in almost any form.

.CNC aggregates will especially find their use in the woodworking, composite, moldmaking industries. They will come in handy where parts require more complex machining, have non-standard shapes, as well as sizes. They allow you to work on a single fixture, resulting in time savings during machining, as well as eliminating operator errors.

Possibility to retrofit the machine with special processing equipment, such as:

.- Drill aggregate - this is ideal when multiple parts of different diameters are required. Configurations are available that allow for both vertical and horizontal drilling.

- Agregate drilling machine.

- Assembly oscillating aggregate - allows for precise cutting of materials such as cardboard, foam, cellular plastics. .

- Agregate with cutting saw - allows efficient cutting of material without changing the attachment, which significantly affects the efficiency and precision of the workpiece. Possible configuration with cutting vertically, horizontally, as well as at an angle. .

- Angle aggregate - allowing to perform the machining process in the selected plane. .

- Specialized aggregate tailored to individual customer needs. .

- Tapping head - an additional module for efficient threading without replacing the tool.

- Tapping head - an additional module for efficient threading without replacing the tool.

- Creasing head - performs processing, thanks to which it is possible to efficiently and precisely bend cardboard, paper, etc. The device is primarily used in the bookbinding industry and advertising industry. .

Example configuration options for 4-axis and 5-axis machining machine:

- The 4-axis configuration - a tilting spindle - significantly expands the machine's spectrum of applications with additional possibilities provided by an additional numerically controlled axis. It is possible to carry out advanced projects with high precision, which affects the competitiveness and attractiveness of the plant's offer.

- The 4-axis configuration - horizontal rotary (turning) axis - allows machining of cylindrical surfaces.

- 4-axis configuration - rotary C-axis on the spindle - a solution that allows the tool to rotate around the Z-axis, allowing the use of multiple precision units for advanced machining. The solution is widely used, especially in the furniture industry.

- 5-axis configuration - tilt-rotary head - thanks to this solution, it is possible to machine in five axes with a single workpiece clamping, which significantly increases the accuracy of workmanship and reduces the time needed to produce a workpiece.

- 5-axis configuration - tilt-rotary table - thanks to the use of two additional numerically controlled axes in the rotary table, it is possible to machine highly complex parts precisely, reducing the need to change workpiece fixturing.

In the Industrial series we have milling plotters on TpaCAD software, which we recommend especially for the furniture industry.

TpaCAD is a complete CAD/CAM for panels. The software has many advanced macros, design tools, the ability to define everything in a parametric way with logical conditions (IF, END IF, ELSE IF).

It is possible to purchase additionally CADnesting software, which is a nesting solution for woodworking with all the options and functions needed in a nesting machine, Intelligent nesting module - allows automatic selection of the cutting path so that as many parts as possible fit on the material. Reduces processing time by reducing cutting costs and keeps waste to a minimum.

For customers who may need to increase the working area in the future, we have innovative modular milling plotters in this series. The idea of this solution is based on the use of, among other things, a special way of fastening and connection in the construction, allowing to expand the working field in the future while maintaining high processing parameters. The solution is covered by intellectual property protection, reserved by ATMSolutions at the European Union Intellectual Property Office (EUIPO), based in Alicante.

.

The machine, with its modular design, is a combination of practicality and usability. Adapting for later expansion increases functionality by adapting the appropriate size of the work area to the user. It expands the machine's production capabilities while maintaining economical upgrade prices. CNC milling plotters ATMS MOD have rich standard equipment, and if you need to increase the scope of the machine's purpose, you can retrofit it with additional equipment and accessories.

The Industrial Series is an advanced solution created to meet customer expectations. We have a dedicated machine model with a Mitsubishi brand robotic arm, which is equipped with a proven vacuum gripper system. This allows automatic loading and unloading of the component without the intervention of a worker in the working field. The control system used allows programming of machining using G-code, among other things. This makes the operation of the station extremely simple and does not require employee training in robot programming.