One of the most common typesóof laser cutter is the CO2 laser The laser beam is created by using a tróingredient gas. It consists of helium, nitrogen and the gas that gives it its name, namely CO2 (carbon dioxide). Cutting is initiated by a pulse of electric voltage. With its help, nitrogen atoms are stimulated to vibrate. Since this gas does not have the ability to emit energy in the form of photonsów (light) it transfers its energy to the molecules of carbon dioxide and these convert the energy of vibrating electronsów into photonów emission.

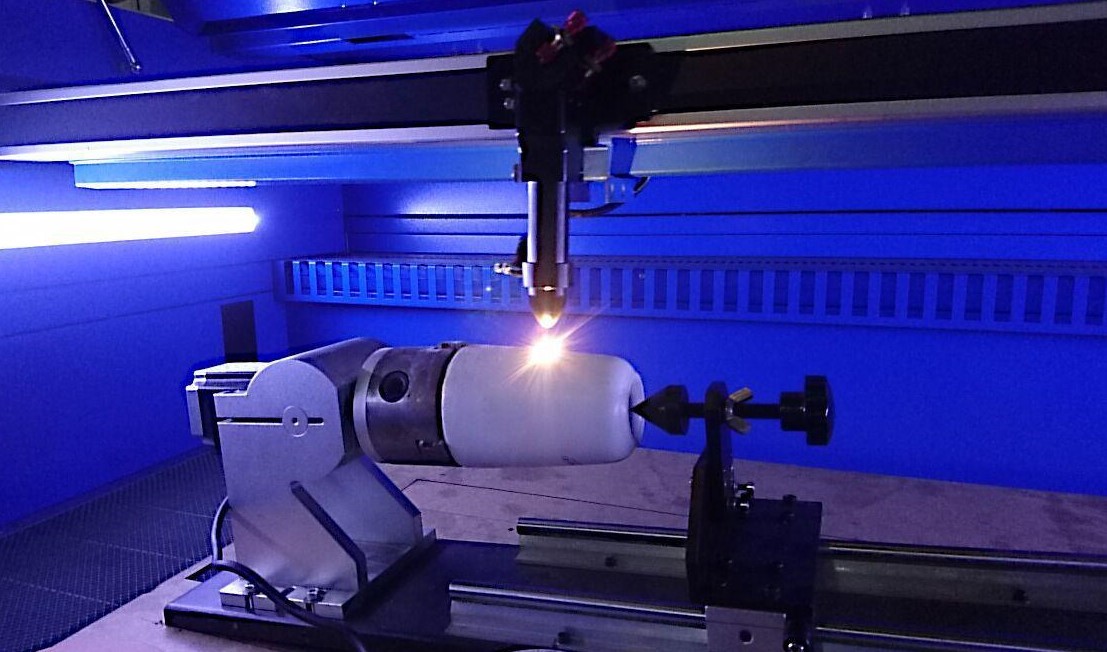

The ever-increasing competition in the market and the ever-increasing requirements for manufacturing time and product accuracy are posing increasing challenges to engineers. In the case of laser plottersóusing numerically controlled CO2 tubes, this “arms race” requiresóhead support for gas lagging cutting. We”ve three most common types of gas”s to assist in laser cutting: compressed air, oxygen and nitrogen.

.Each of the administered gasesós protects the lens from splinters and vapors, as well as cools the edge of the material being cut and blows the molten metal and resulting oxides off its surface.

CO2 laser schematic [based on 1].

..

1. AIR

.We can use it to defendómaterials such as plastics or wood and wood-like materials. This is the cheapest solution amongós discussed. To use this method, you need to equip the laser plotter with a source of compressed air (such as a compressor). When working with compressed air, we can get more accurate edges, as the stream directed at the material will prevent it from igniting or melting. It will also have a positive effect on the machining time, as by using compressed air we can increase the speed of the laser head movement. In the case of plexiglass, a stream of compressed air will prevent the elementsós sticking together. Without gas support, it is possible to ignite or melt the workpiece. Cutting with compressed air is called flame cutting.

.

2. Nitrogen

.Nitrogen assisted cutting is classified as high-pressure cutting, used in high-powered plotters. The material is melted with a laser jet and then blown out of the resulting slit. The increase in nitrogen pressure makes it possible to achieve a higher cutting speed; unfortunately, this is limited by the cooling effect of the injected gas. Cutting with nitrogen lagging does not emit additional heat, as there are no chemical reactions between the gas and the metal being cut.

This is a very versatile booster gas. We can use it when working with materials such as acid-resistant steel, brass, non-ferrous metals, thermally conductive materials, (copper, titanium). As in the case of the previously discussed air, by increasing the pressure of the injected gas we can work with a higher speed of the laser head. The pressure with which nitrogen is fed reaches up to 22 bar. The most important issue with nitrogen assist is its purity. Even the slightest contamination with oxygen can lead to a decrease in the quality of the edge of the material being cut. Oxidizing material can leave chew marks on the cutting edge.

Cutting with nitrogen is called sublimation or fusion cutting. For materialsóre that do not have a melting point, the sublimation method is used. During such a process, the material goes directly from solid to gas. Materials subjected to such a process include: wood plywood, plexiglass, ceramics.

.On the other hand, in the case of fusion cutting, the material is heated to its melting point and then blown off by a gas with a pressure of up to 22 barów.

.For materialsów such as titanium, zirconium, Magnesium nitrogen is replaced by argon. Argon, unlike nitrogen, does not form chemical bonds with the aforementioned elements.

3.TLENE

.When cutting with oxygen, the material is burned and vaporized. Oxygen pressure can be increased to increase efficiency. The limitation for oxygen-assisted CO2 laser cutting is side burning caused by too much oxygen pressure, rather than the cooling effect as with other gasesów This can result in improper cutting. This gas is not as versatile as the aforementioned nitrogen.

The material must meet two conditions:

.- the ignition of the metal must take place at a temperature lower than its melting point, .

- the melting of oxidesós formed during cutting takes place at a temperature lower than their ignition. .

During cutting, a reaction takes place between the material and oxygen molecules fed under pressure giving additional heat energy. By increasing the oxygen pressure, we also increase the efficiency of material blowing. Oxygen assistance is recommended for machining non-metals, black sheet and galvanized sheet.

.

SUMMARY:

.The described lagging gases make it possible to accelerate the machining of materialsó. Depending on the material to be machined and the selection of the appropriate gas, we can optimize working conditions and reduce material waste caused by the need to reject imprecisely cut partsós. In addition, with the help of lagging gases, the range of processed materialsós can be expanded due to the possibility of cutting much thicker sheets. Supporting cutting with gasesós also has one major advantage – it allows working on materials prone to ignition within the cutting edge, preventing them from burning, and thus improving the quality of the cut surface.

From the examplesó presented, it can be deduced that the most versatile booster gas is nitrogen. It is used for machiningóing almost all of the most common materialsóing we encounter during various engineering works. In addition, nitrogen is readily available and easy to obtain, since its share of air composition is about 80 percent, which makes a significant difference in the cost of purchase.

Resources:

[1] http://old.messergroup.com/pl/Informacje_techniczne_i_katalogi/Katalogi/Ci__cie_i_spawanieCiecie-laserowe.pdf

[2] https://www.icd.pl/poradnik/post/technika-ciecia-gazowego

[3] http://www.grawerowanie-lublin.pl/dzialanie-lasera-co2,202.html

[4] http://www.airproducts.com.pl/Industries/Transportation/Aerospace/aerospace-Metal-Fabrication/product-list/laser-cutting-aerospace-metal-fabrication.aspx?itemId=2F82E36E6900410782A393A1F2590782

[5] https://www.lindegaz.pl/pl/processes/cutting_joining_and_heating/cutting/laser_cutting/laser_cutting_with_nitrogen/index.html

[6] http://www.pspaw.pl/index.php/pspaw/article/viewFile/289/291